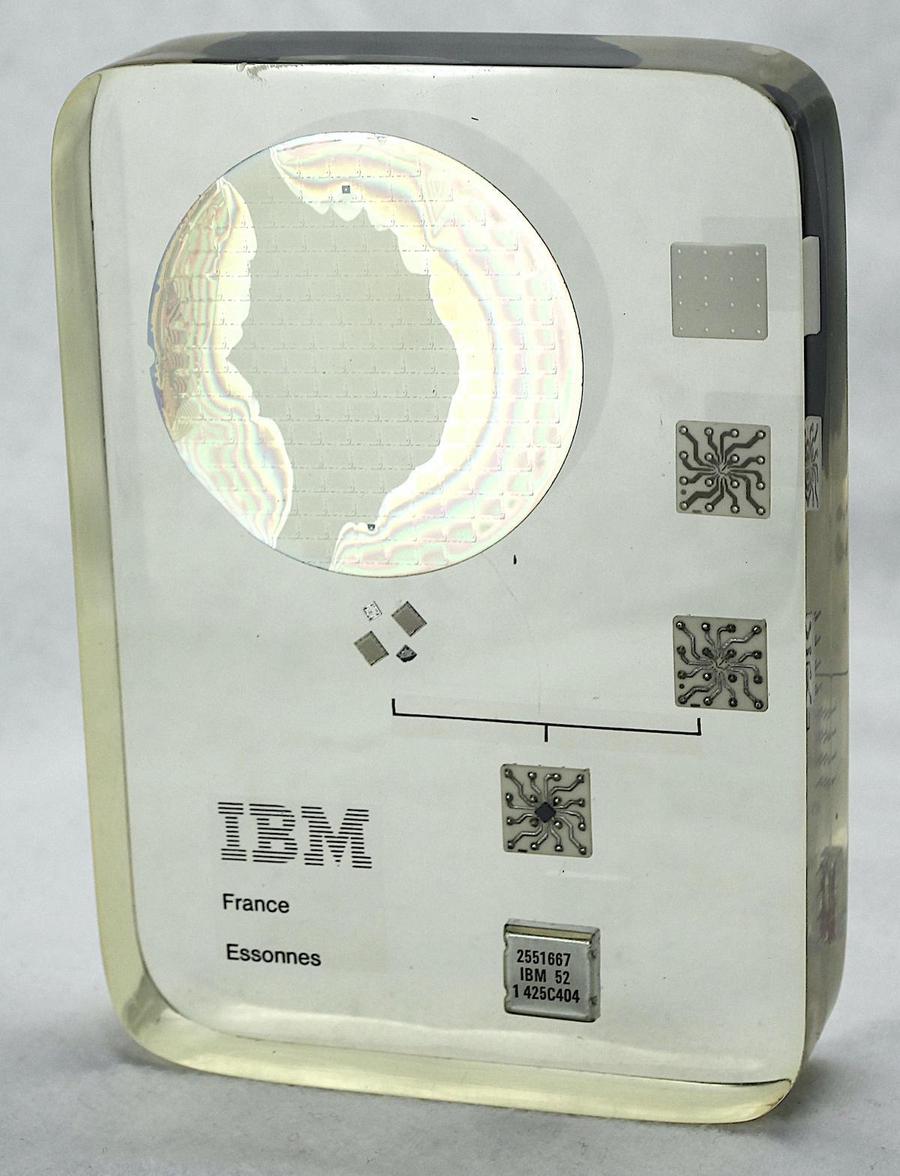

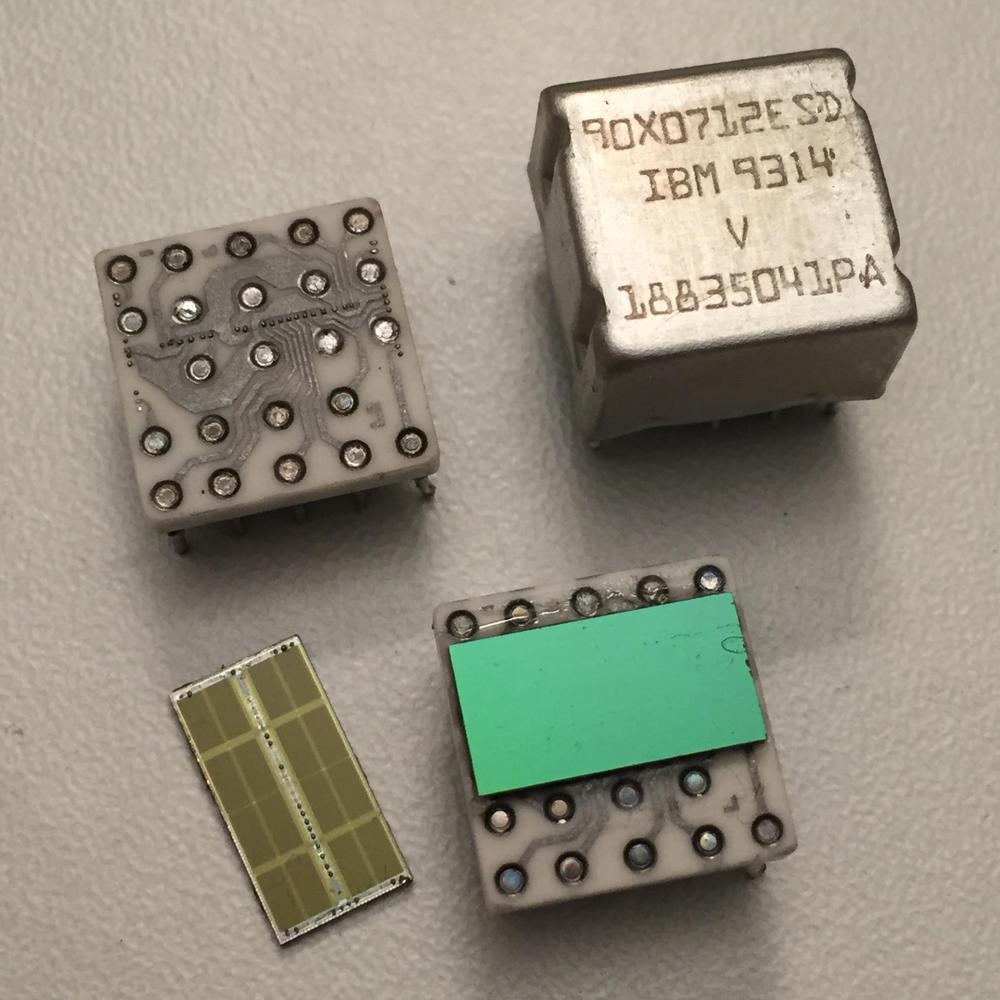

I recently received a vintage IBM paperweight from the early 1970s that showcases some memory chips.1 When IBM started using integrated circuits in the late 1960s, they packed the chips in square metal modules called Monolithic Systems Technology (MST). The paperweight illustrates the manufacturing steps for an MST module as a silicon wafer was cut into silicon dies, mounted on a square ceramic substrate, and wrapped in a thumbnail-sized metal package.

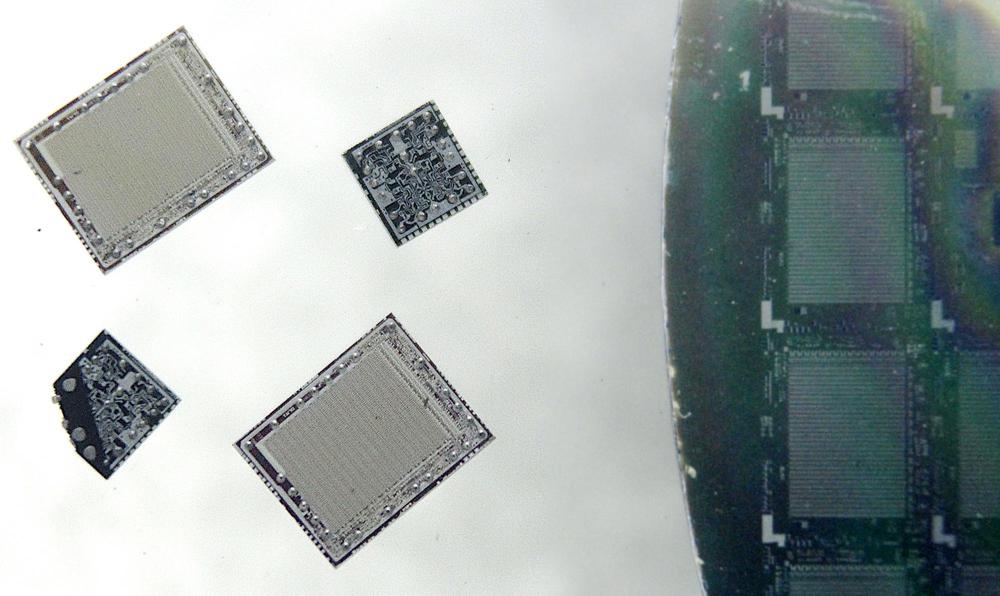

Because the dies are encased in clear Lucite, it's possible to closely examine their circuitry and understand them better. The photo below is a closeup of the edge of the silicon wafer and the four dies inside the paperweight. The two larger dies are the same as the dies on the wafer. The two smaller dies are the same, but one is visibly damaged.2 For this blog post, I took detailed die photos using a microscope and reverse-engineered the smaller chip. My conclusion is that the larger chips are 1-kilobit static RAM chips, while the smaller ones are memory sense amplifiers.

IBM System/370

These chips were probably used in IBM's popular System/370 line of mainframe computers. In 1964, IBM introduced the extremely successful System/360 family of mainframes. This product line was modernized in 1970 with the announcement of System/370, which was constructed from integrated circuits (unlike the System/360) and moved from magnetic core memory to semiconductor memory. The paperweight illustrates both of these changes: integrated circuits and semiconductor memory.

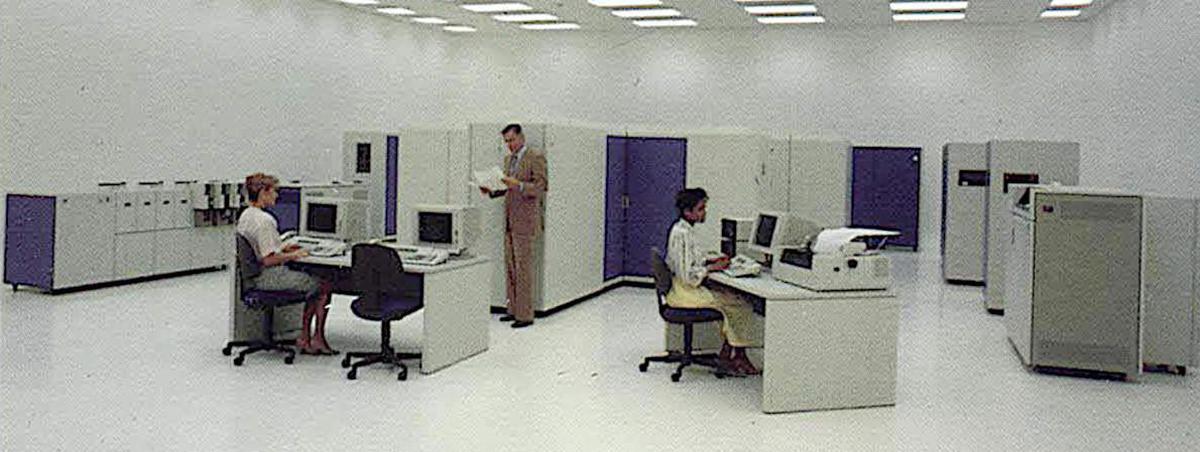

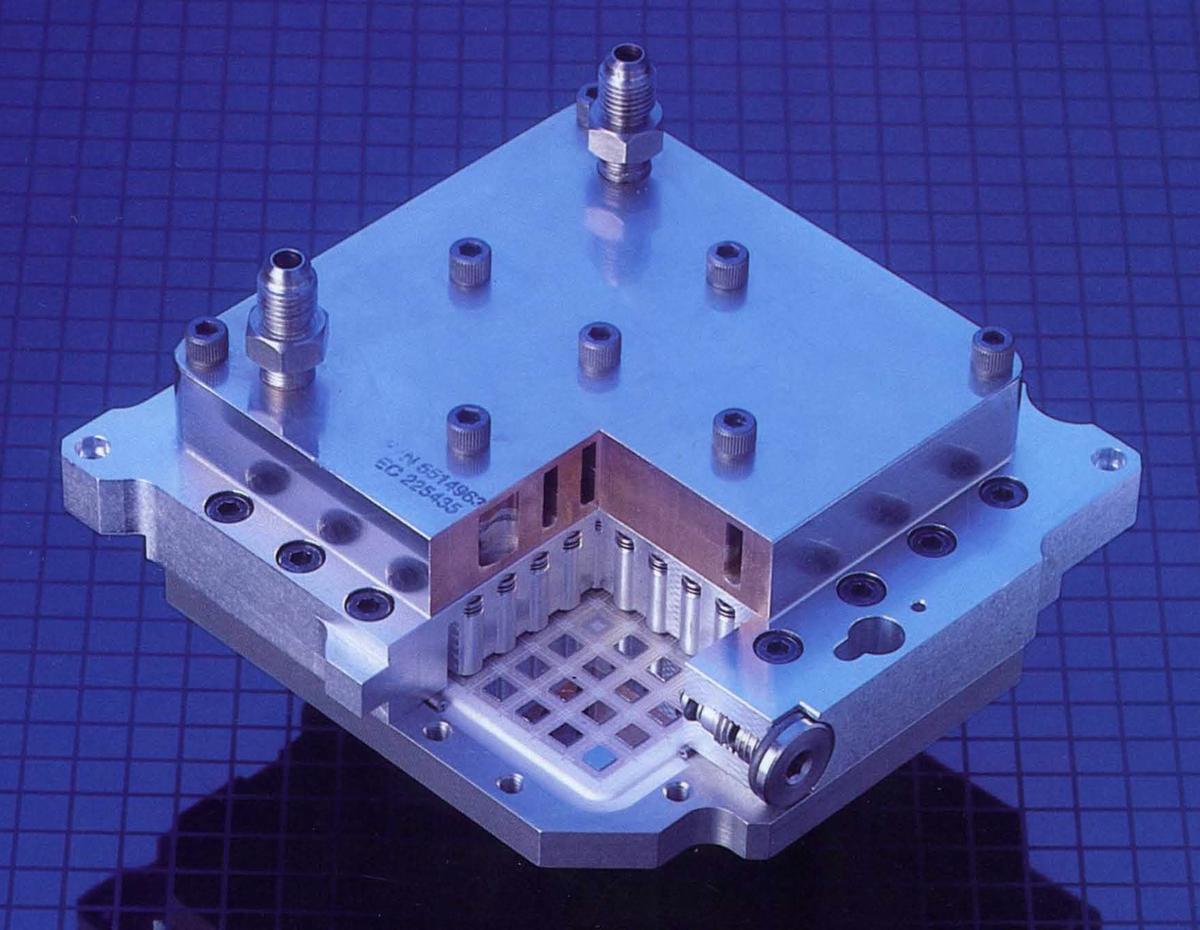

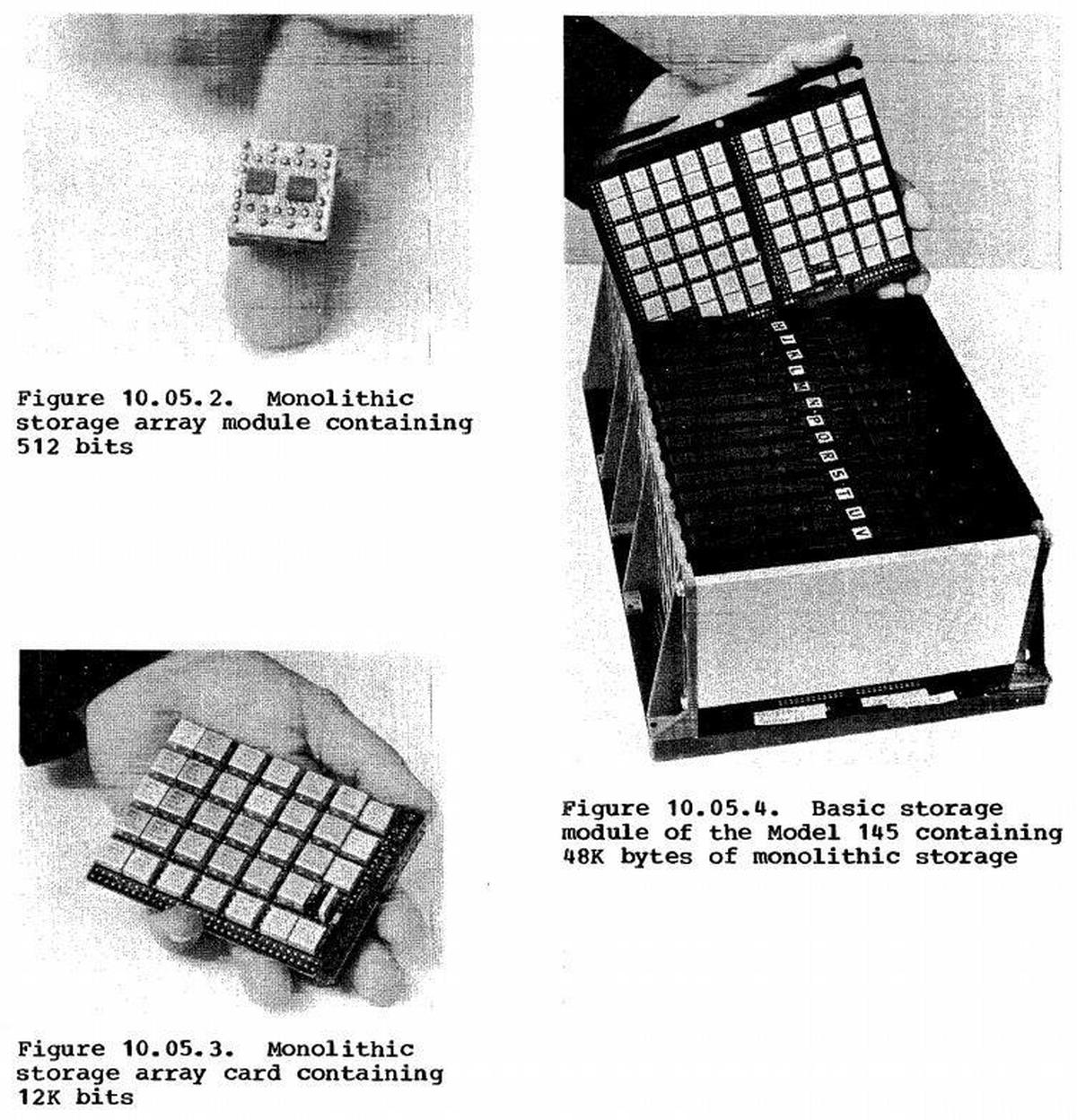

To understand the scale of a System/370 computer, the rendering below shows a System/370 Model 145. The Model 145 was a "medium-scale" machine in the middle of the System/370 family.3 The Model 145 is notable as IBM's first computer that used semiconductor main memory. The computer is very large by modern standards, filling the blue cabinets below. One cabinet holds the CPU while another holds 256 kilobytes of memory chips. This computer predates the microprocessor, so the CPU is built gate-by-gate from many boards of integrated circuits. The Model 145 weighed over a ton, cost $5 to 10 million (in current dollars), and was roughly as fast as an IBM PC (1981).

The MST modules

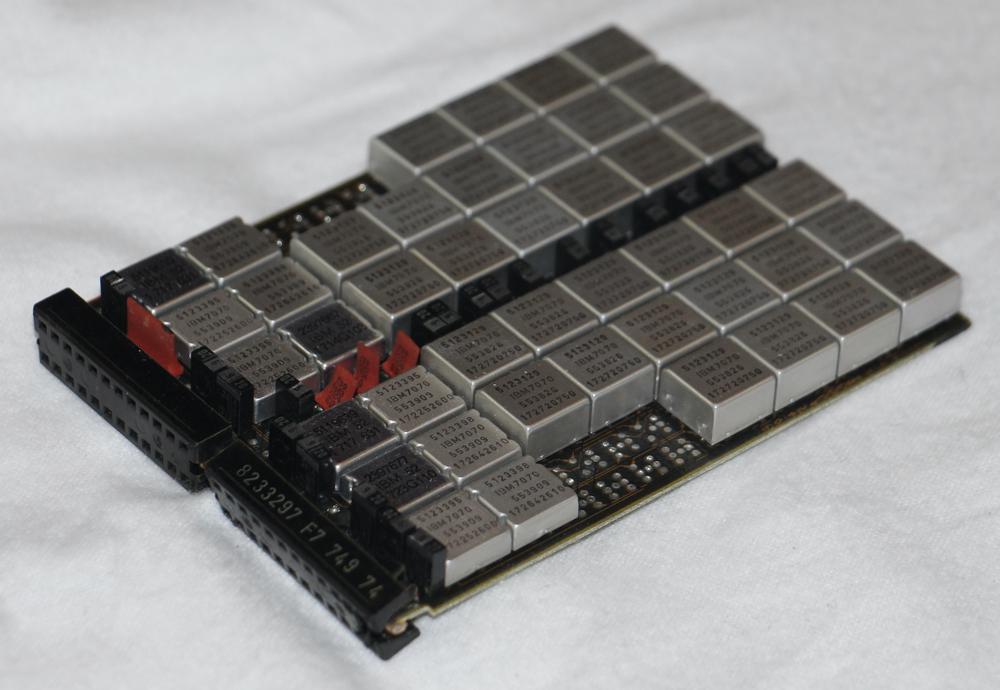

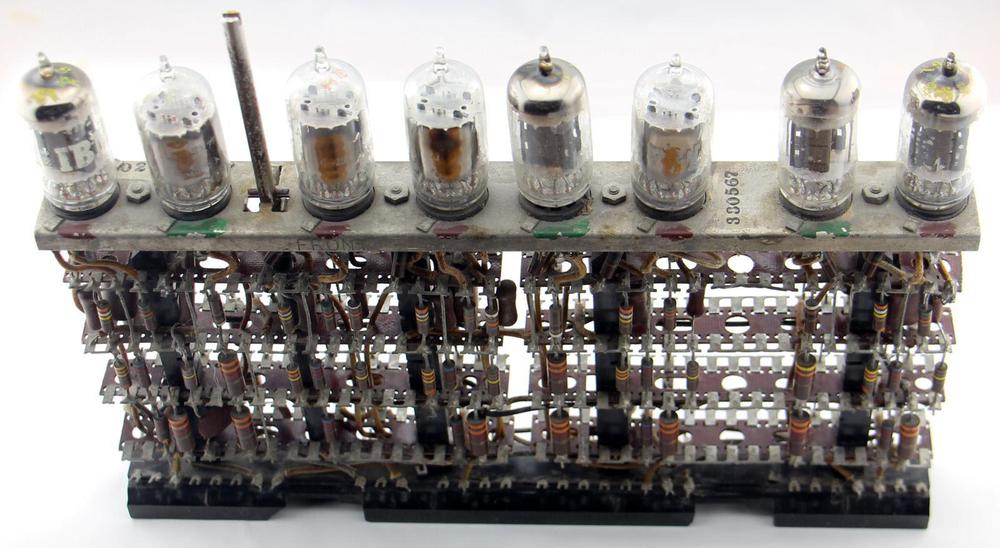

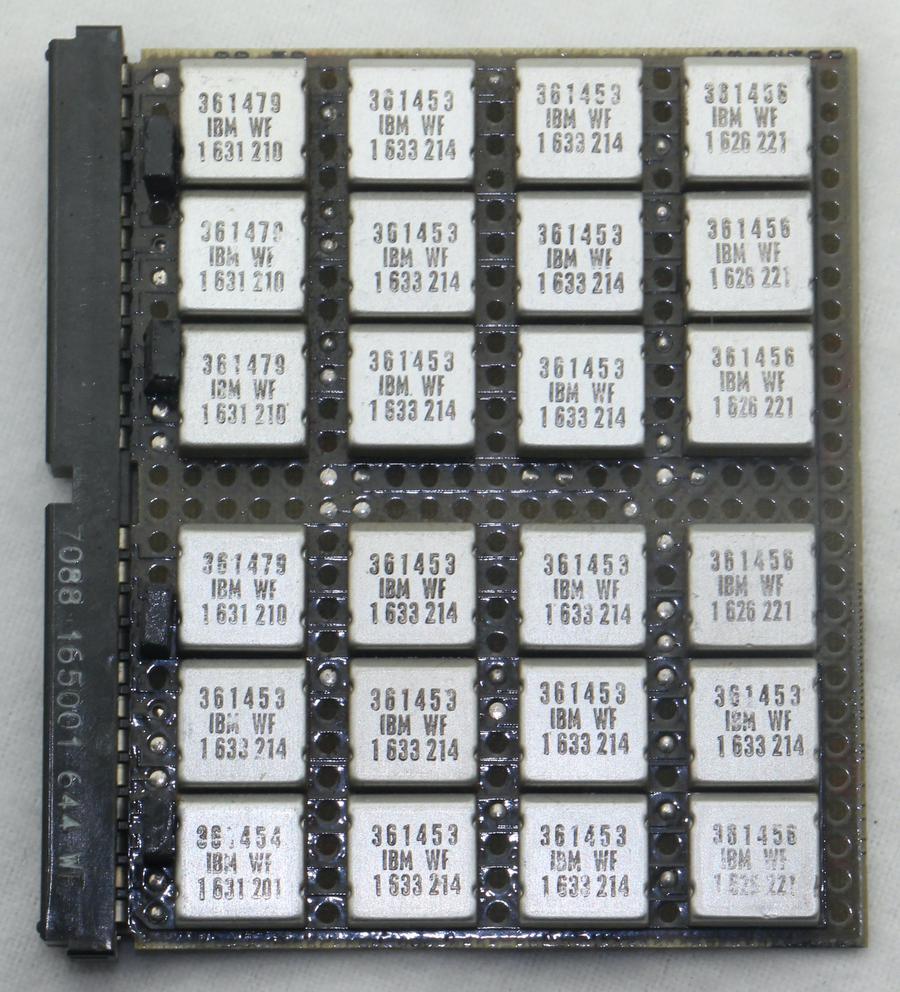

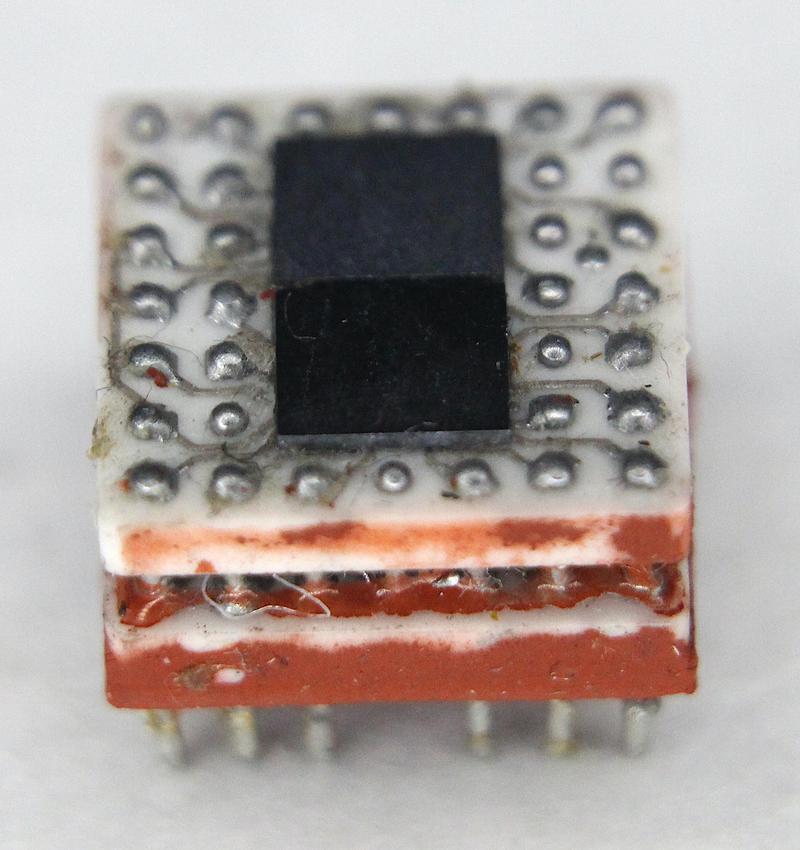

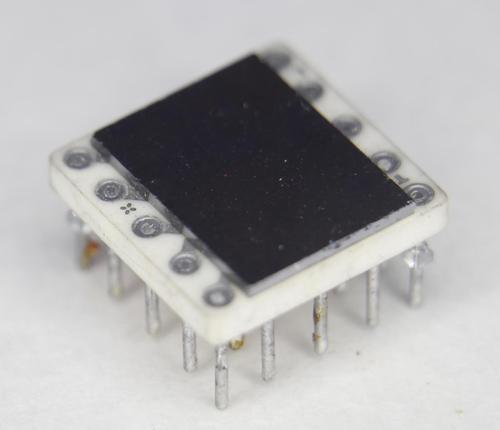

In the earlier System/360, IBM didn't use integrated circuits, but instead used hybrid modules called SLT. For the System/370 IBM moved to integrated circuits, which they called "monolithics". While most companies packaged integrated circuits in rectangular plastic or ceramic packages, IBM retained the half-inch-square metal packages of SLT, calling it MST, for Monolithic Systems Technology.4 MST was a big improvement over the earlier hybrid SLT, about ten times more reliable and 4 to 8 times as dense. These MST integrated circuits were very simple by modern standards, with 32 transistors per module implementing about six gates, so thousands of integrated circuits were required to implement the computer.

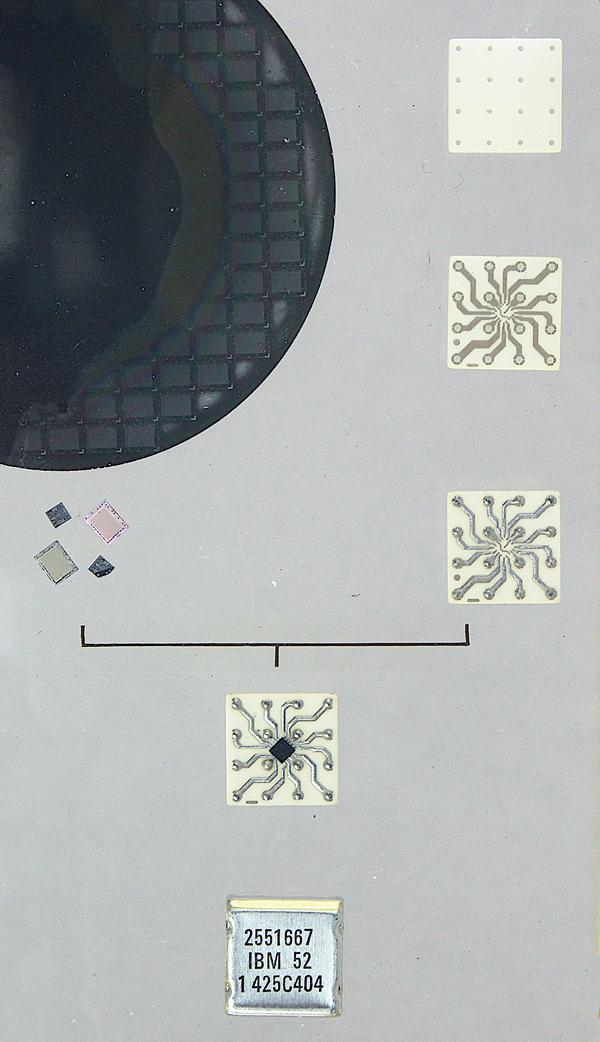

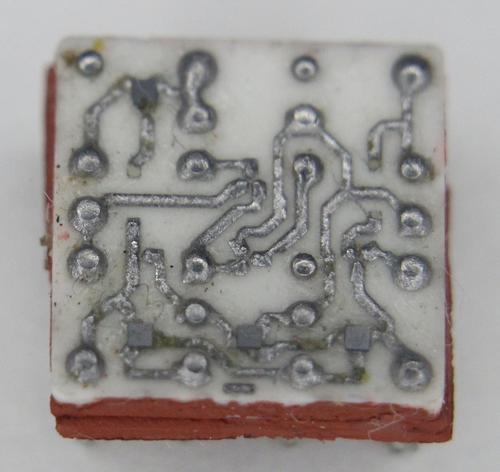

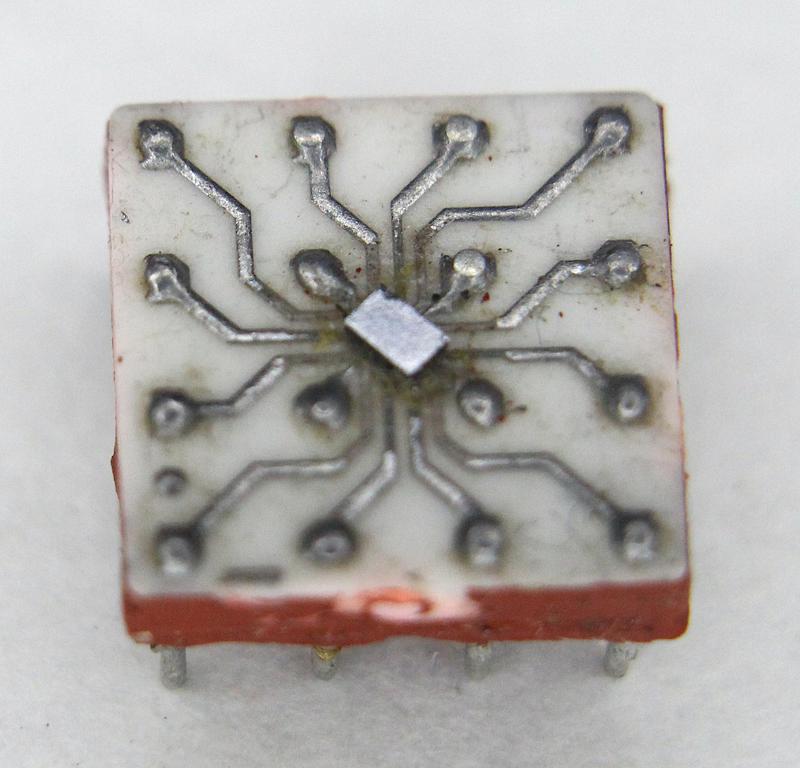

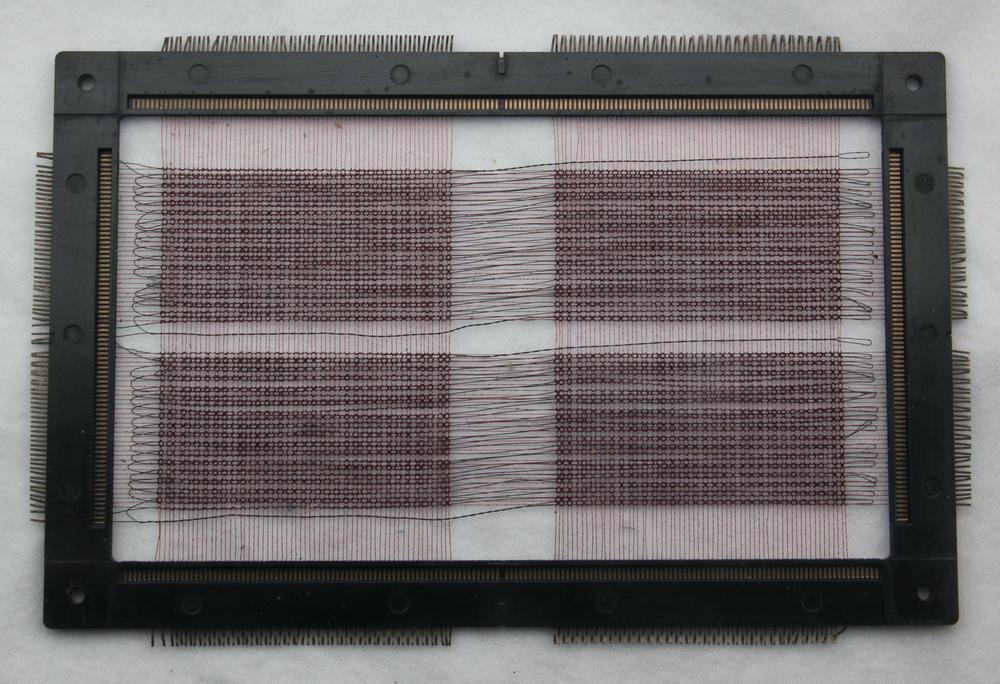

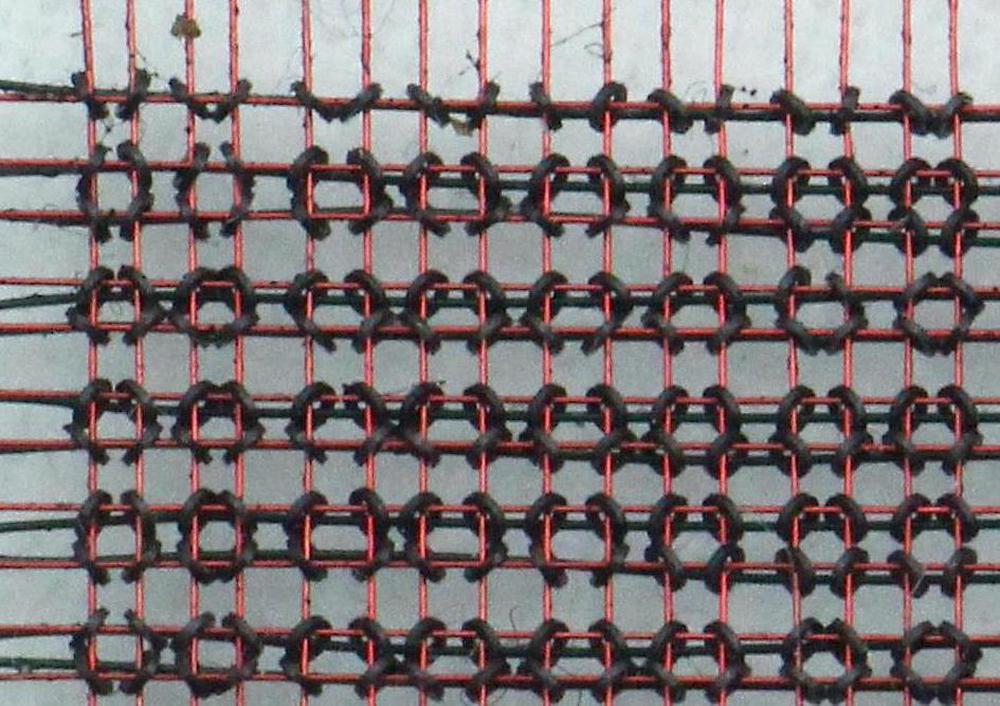

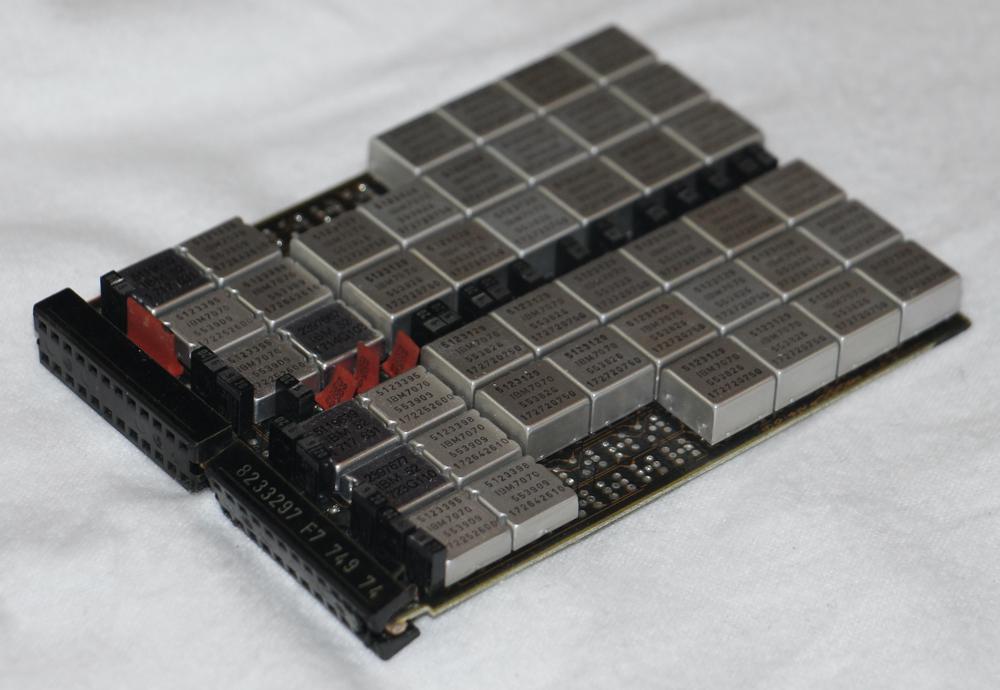

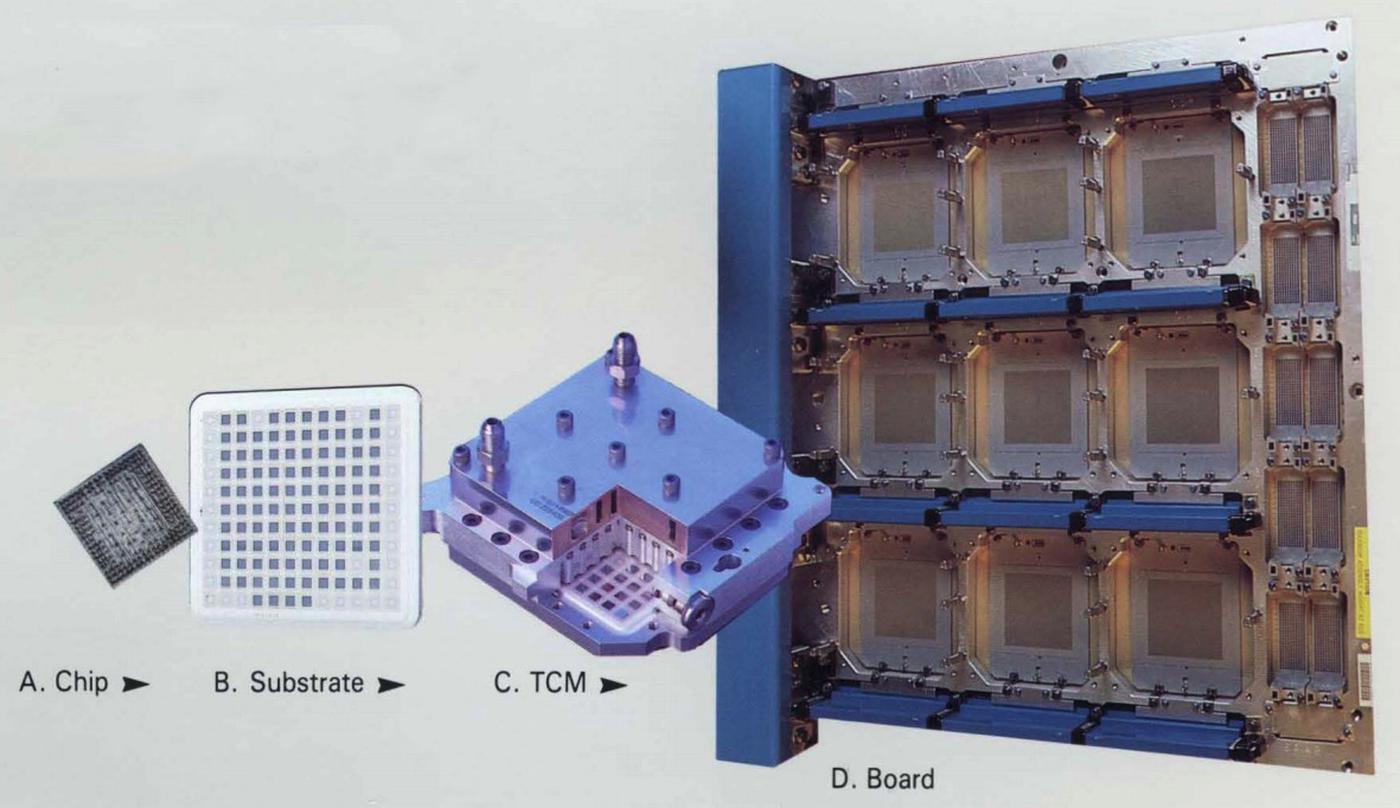

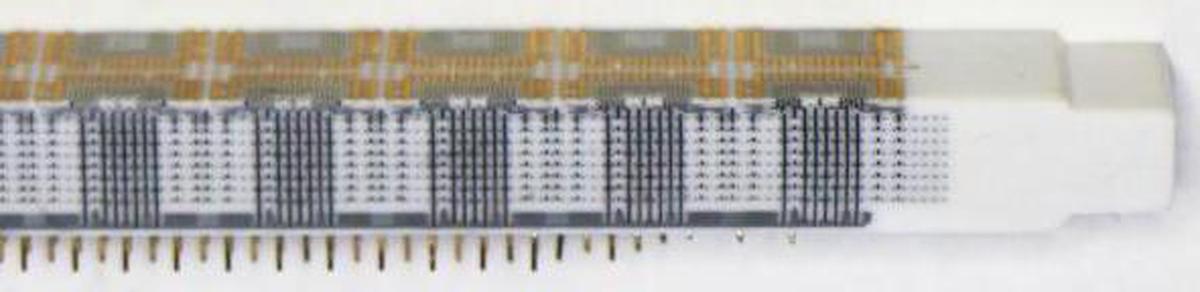

The MST modules were manufactured in large quantities with automated production techniques. The sequence of components in the paperweight (below) illustrates the steps. On the left, the round silicon wafer is cut into individual dies. On the right, the square ceramic substrate has 16 holes for pins. Next, a printed-circuit pattern is applied to the substrate to connect the integrated circuit to the module's pins.5 In the third step, 16 pins are soldered to the substrate. Next, the silicon die and the ceramic substrate are combined, with the silicon die is mounted upside-down in the center of the ceramic substrate. Note how small the silicon die is, compared to the size of the package. The module is reflow-soldered, with contacts on the silicon die soldered directly to the substrate.6 Finally, the module is encased in metal, producing a half-inch square module. These modules give IBM's integrated circuits a unique appearance, distinct from the plastic or ceramic DIP integrated circuits used by other manufacturers.

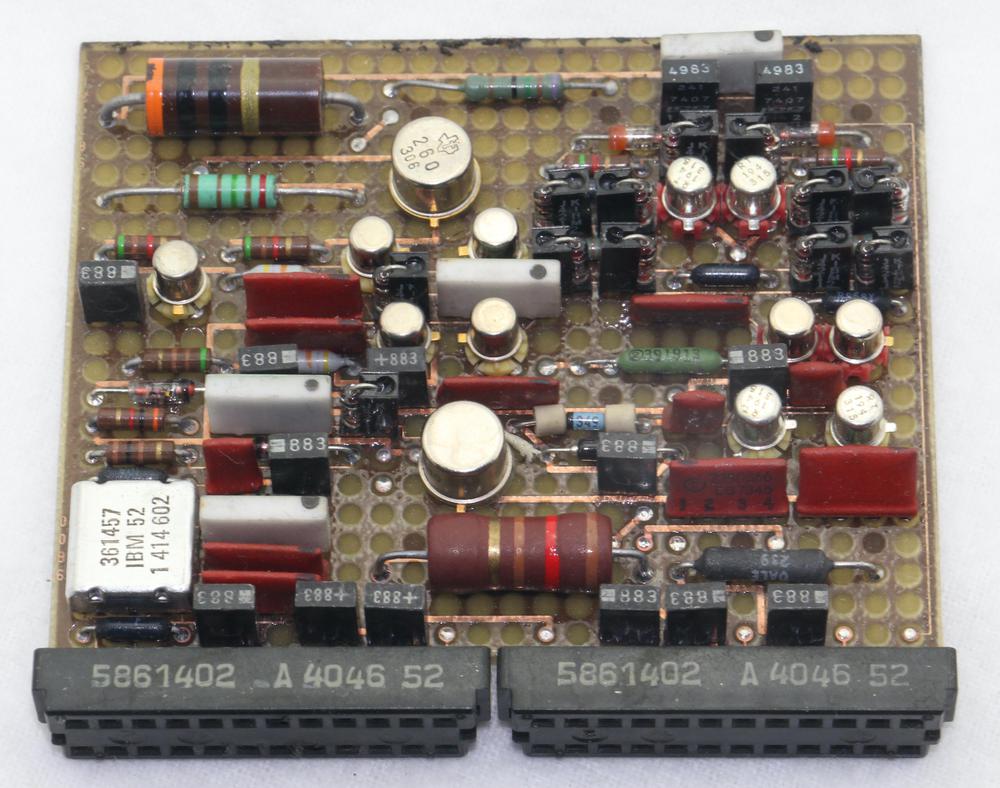

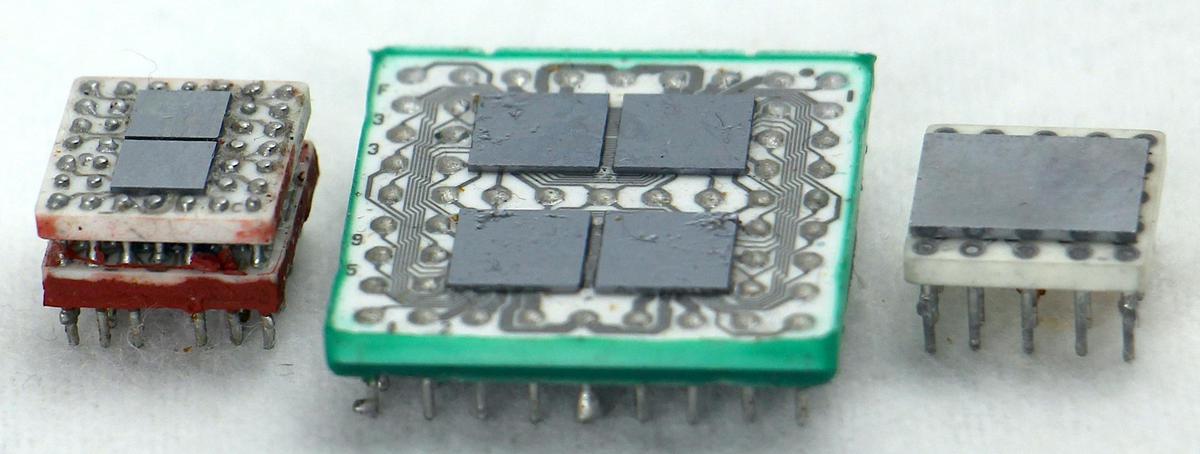

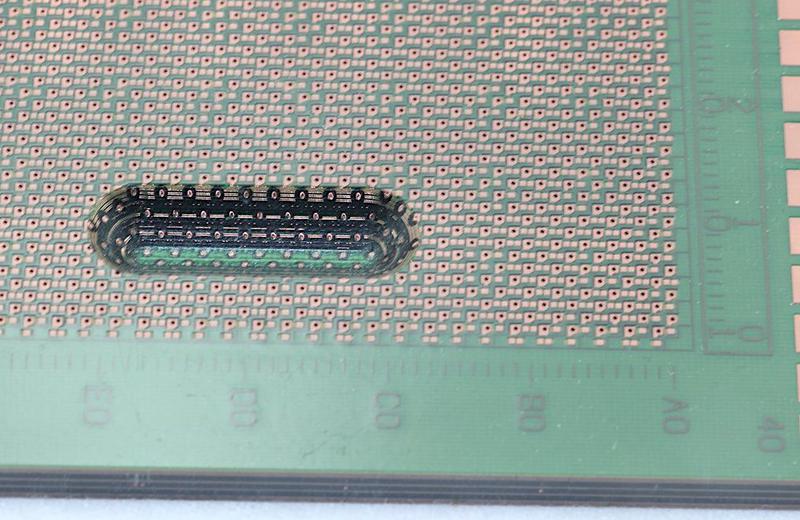

The MST modules were tightly packed on circuit cards, such as the memory card below. The square module in combination with a four-plane printed circuit board provides considerably higher density than the circuit boards of other manufacturers at the time, which typically used DIP integrated circuits and 2-layer PCBs.

The memory wafer and chip

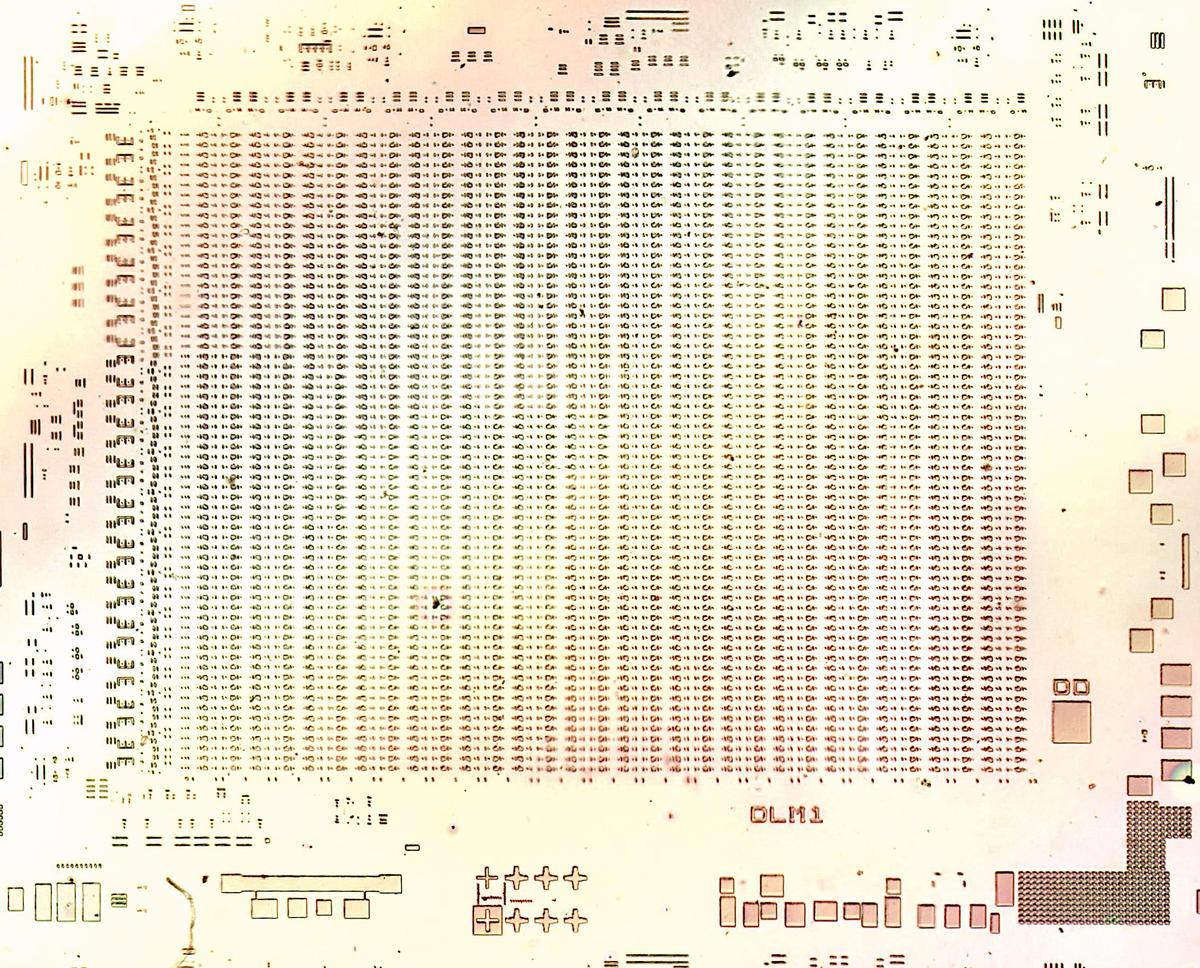

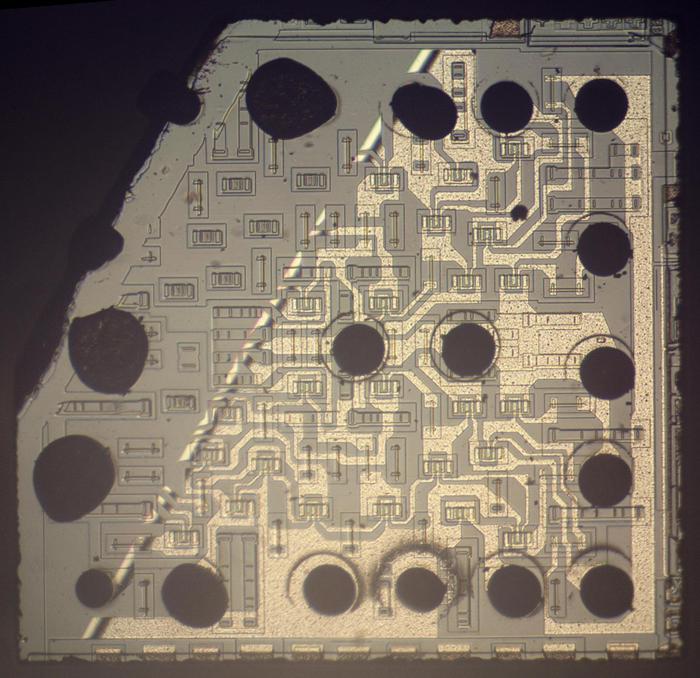

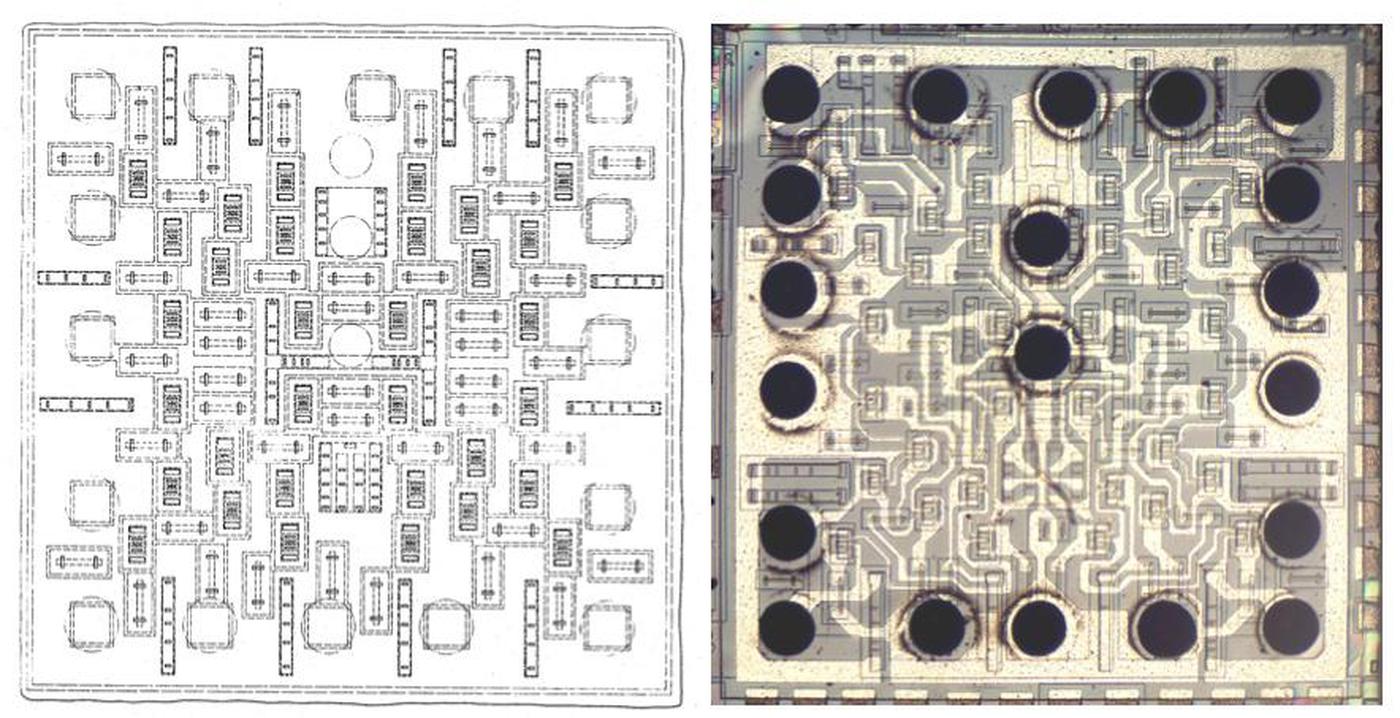

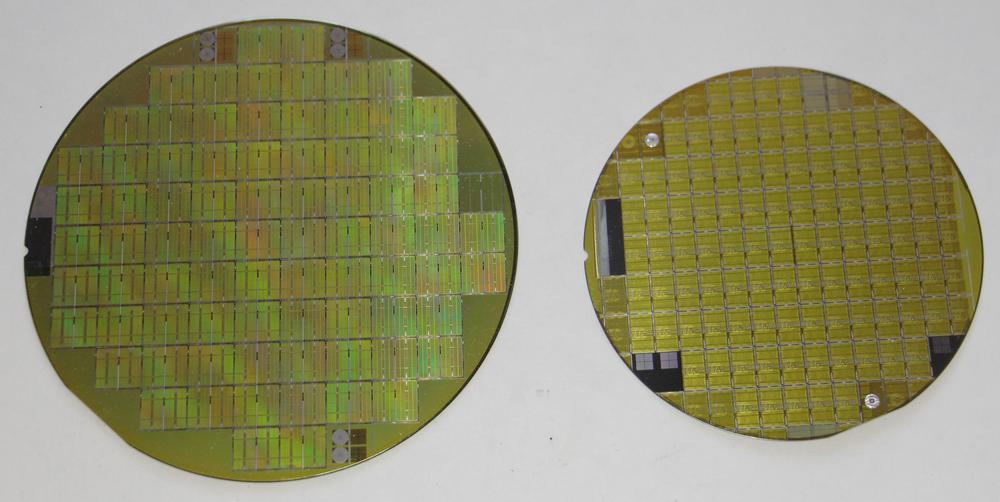

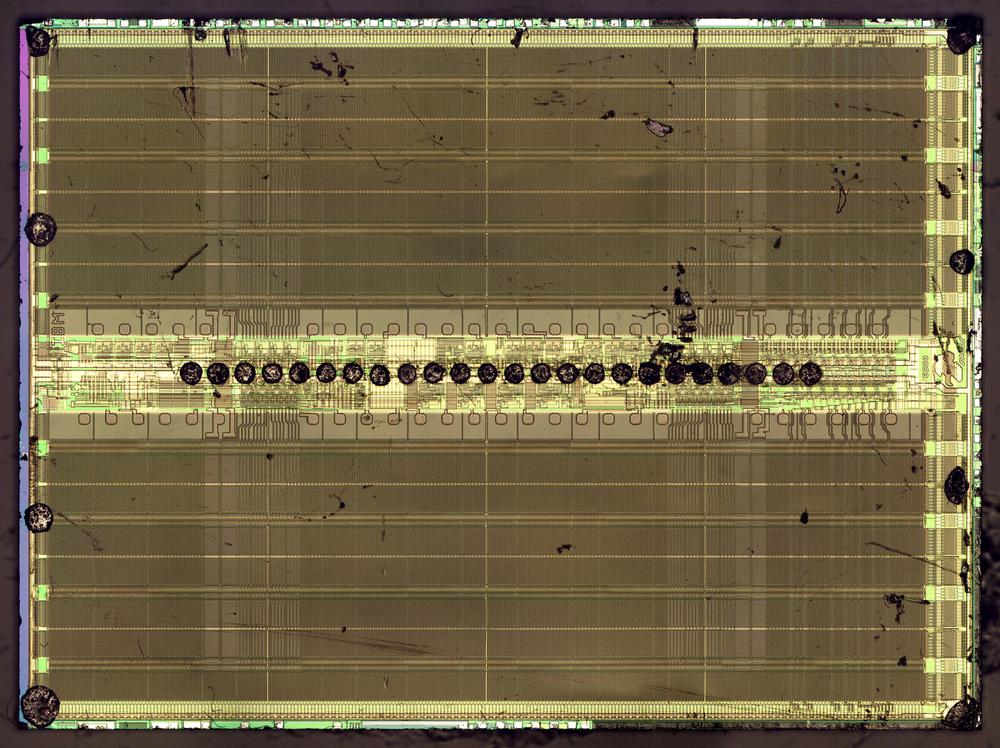

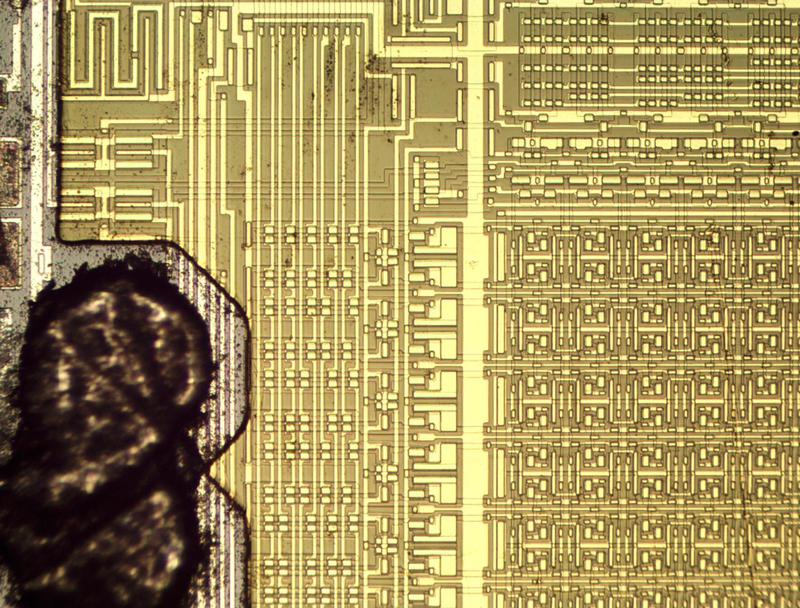

The silicon wafer in the paperweight is 2 inches in diameter, a size that was introduced in 1969. Wafer sizes have steadily increased since then and modern chip fabrication is done with much larger 300 mm (12") wafers.7 The wafer contains 177 dies; using a microscope, I created the die photo below of one of them. Curiously, the wafer is only partially manufactured; it looks like only one of the nine mask layers was constructed. Because this photo is taken from the wafer, you can see the test circuitry and alignment patterns in between the dies.

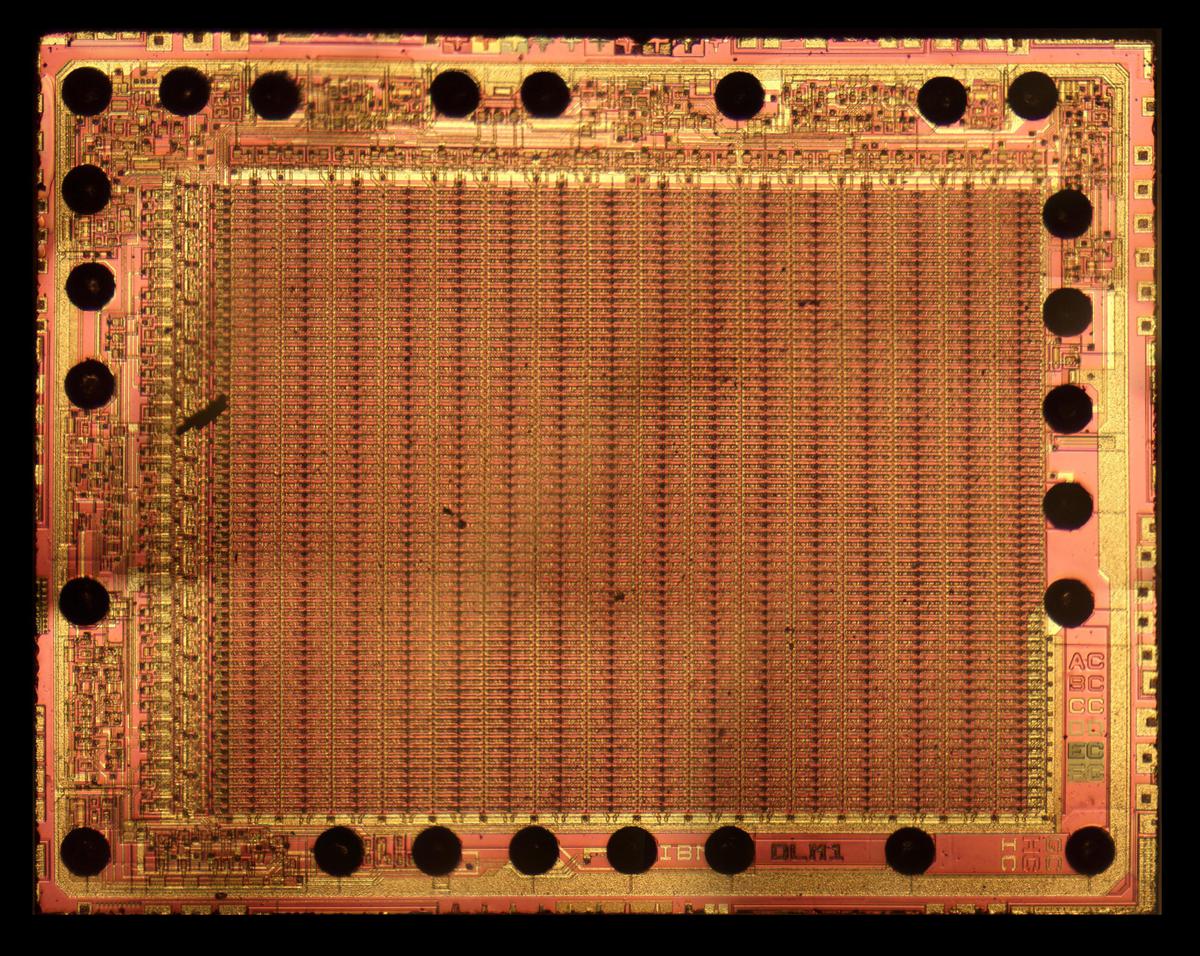

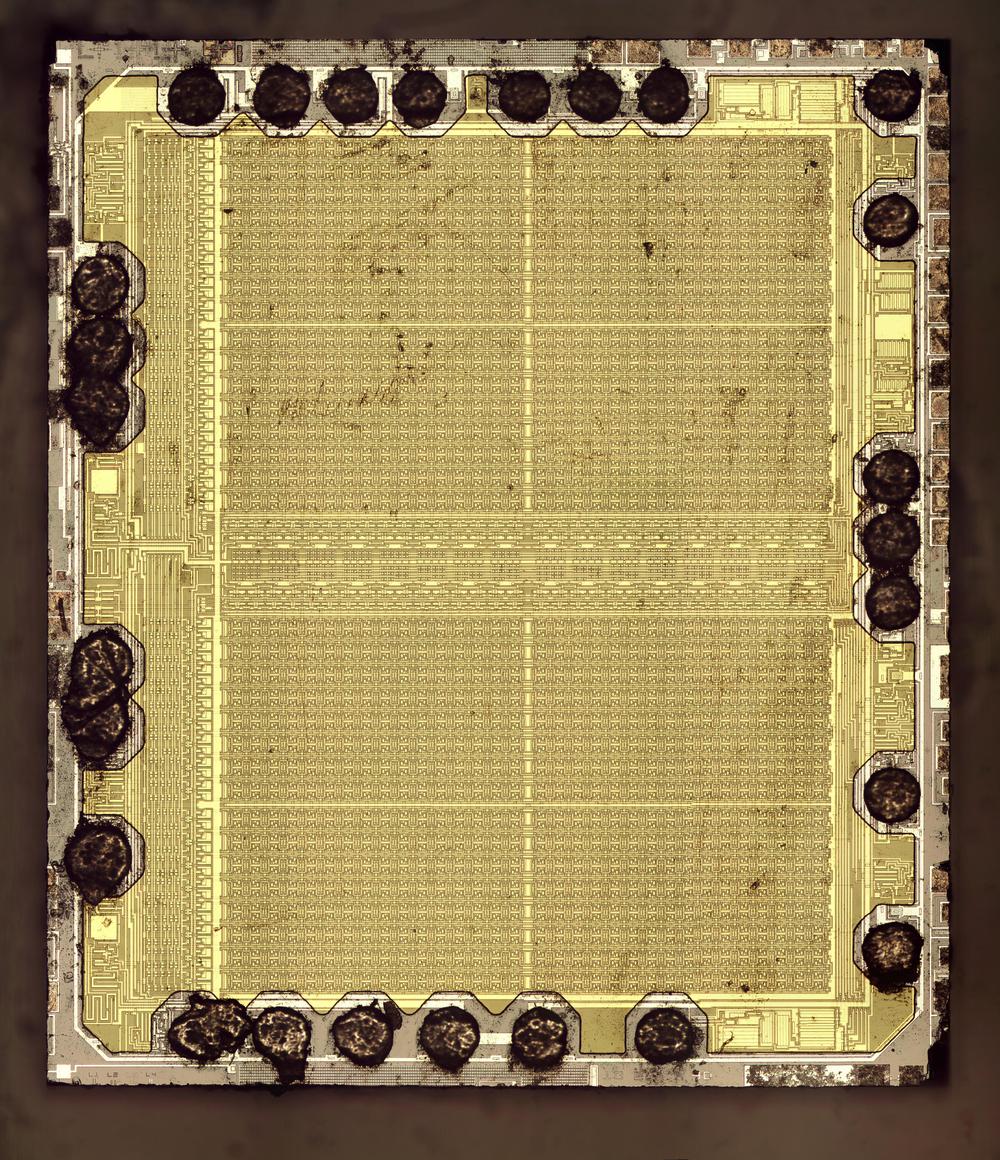

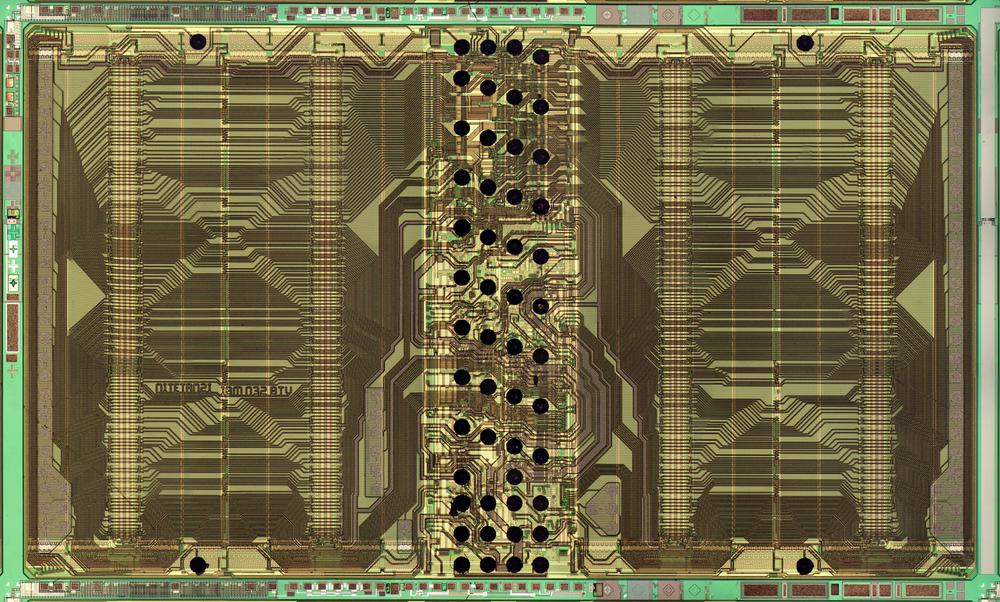

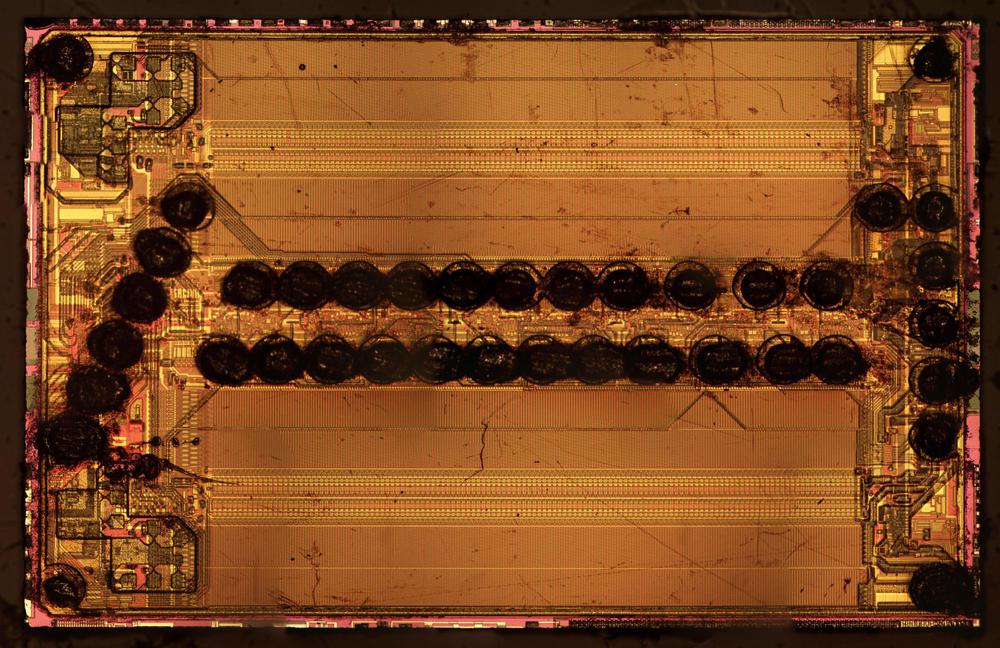

The paperweight also contains completed individual dies so I created the die photo below. The regular grid of memory cells is visible in the middle of the chip, with support circuitry around the edge. From studying the die and counting the cells, I think this is a 1-kilobit static RAM chip. Note the solder balls around the edge of the die, which allowed the chip to be soldered directly to the ceramic substrate. With 25 solder balls, this chip was probably mounted in an MST package with a 5×5 grid of pins.

Taking microscope photos is difficult when the die is encased in Lucite, so I wasn't able to see the circuitry under high magnification. As a result, I couldn't reverse-engineer this chip in detail.8 I was able to measure the feature size on the die as about 6µm, a process introduced around 1971.

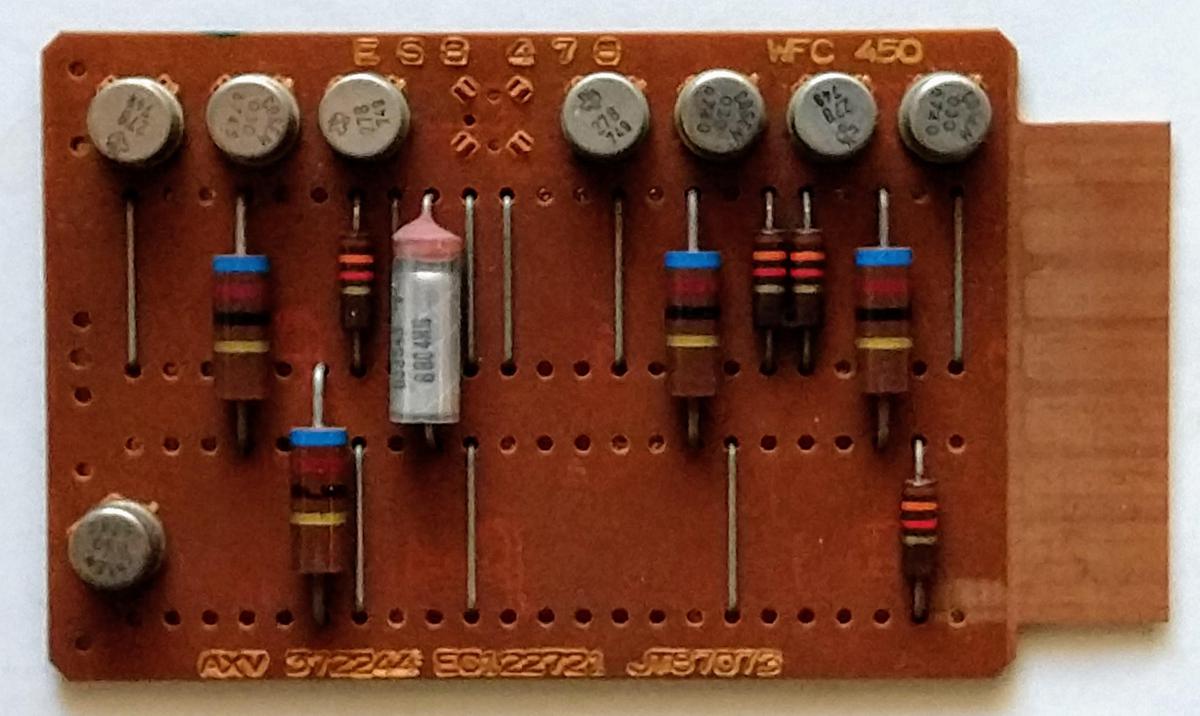

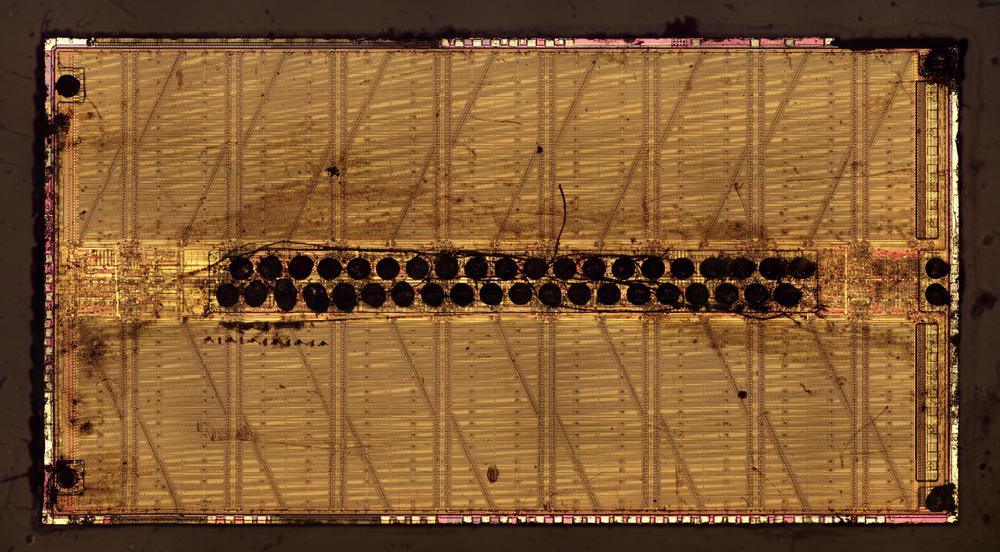

The sense amplifier chip

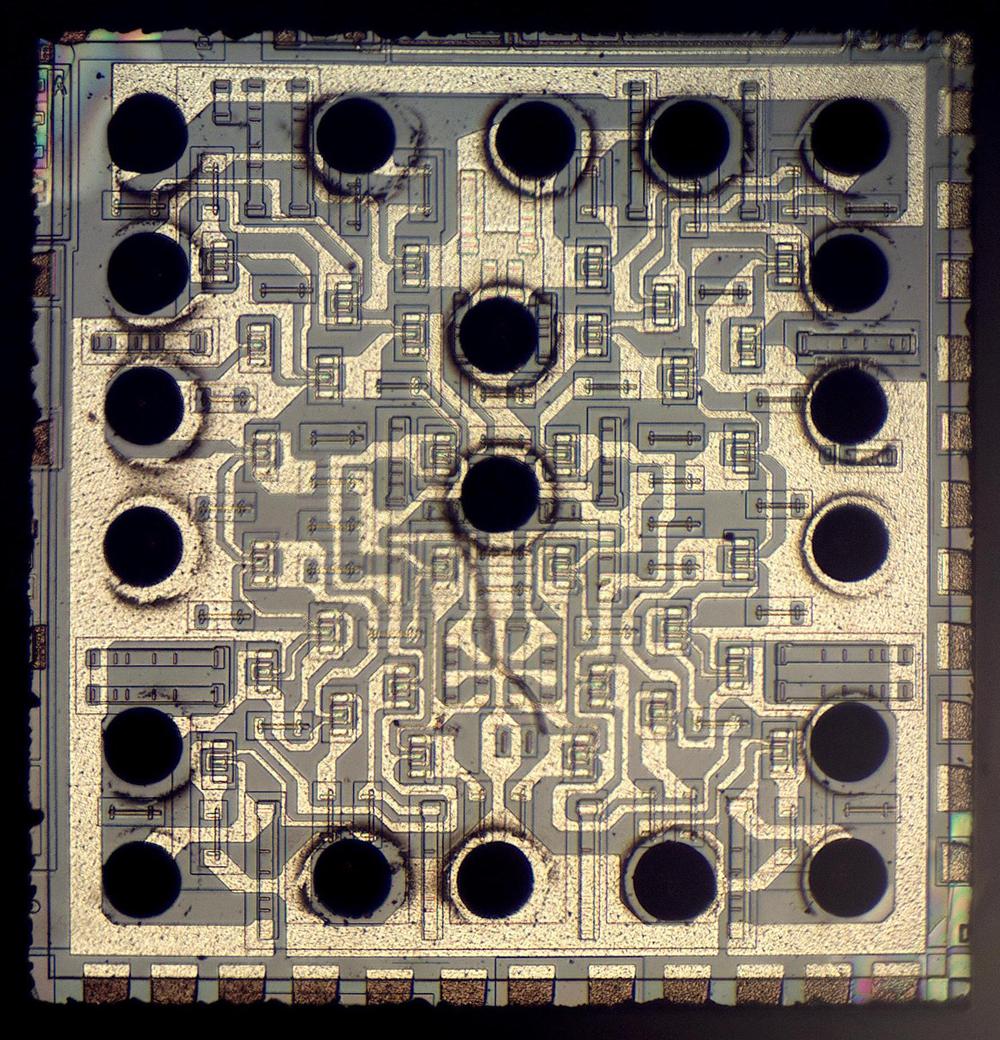

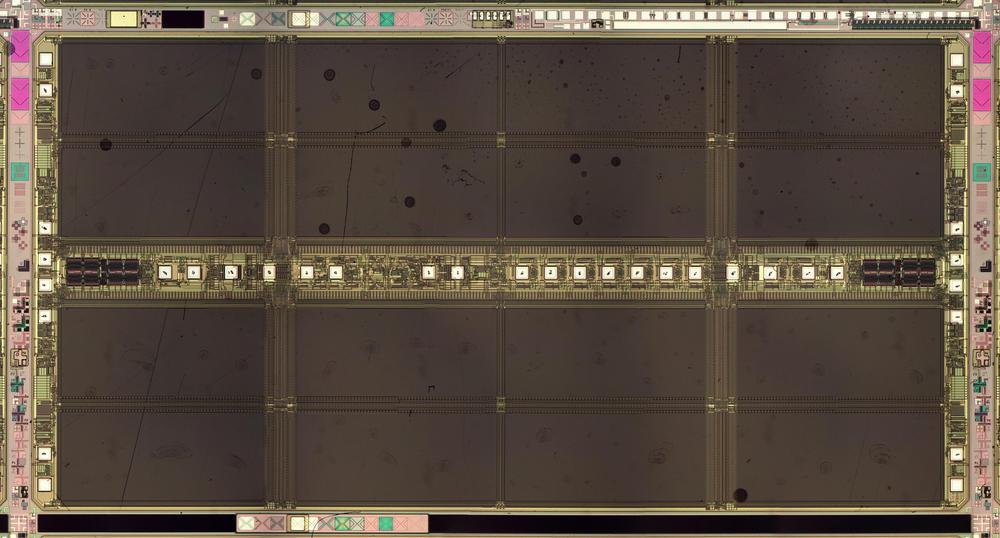

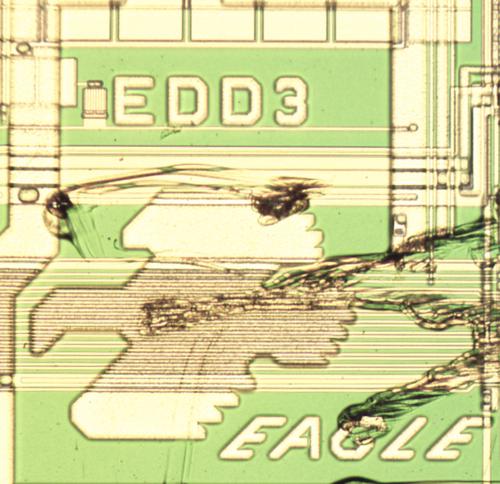

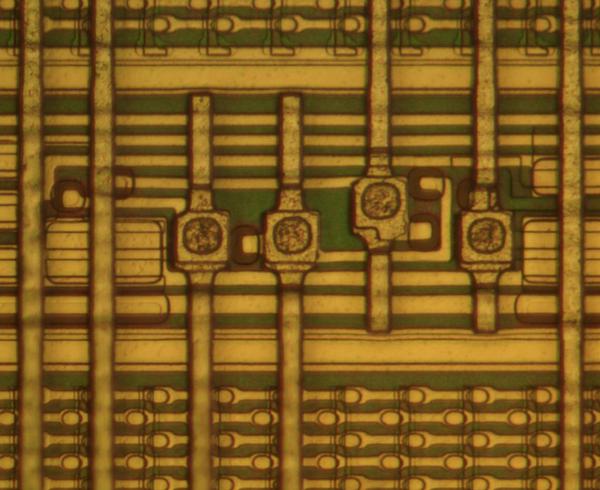

The smaller die in the paperweight is much simpler with much larger components. I took the die photo below and found it contains 32 NPN transistors along with resistors. This chip is partially analog and also uses a type of logic called ECL. I believe the chip is a differential amplifier, a sense amplifier to read the signals from the memory chip. This would explain why the two chips are packaged together in the paperweight.

In the die photo above, the silicon of the die is gray. Parts of the silicon were doped with arsenic, boron, or phosphorus to create regions with different semiconductor properties. The black lines in the silicon are boundaries between different doping levels. The yellowish regions are metal wiring on top of the silicon, connecting the various components together. The large black circles are the solder balls to connect the die to the MST substrate.

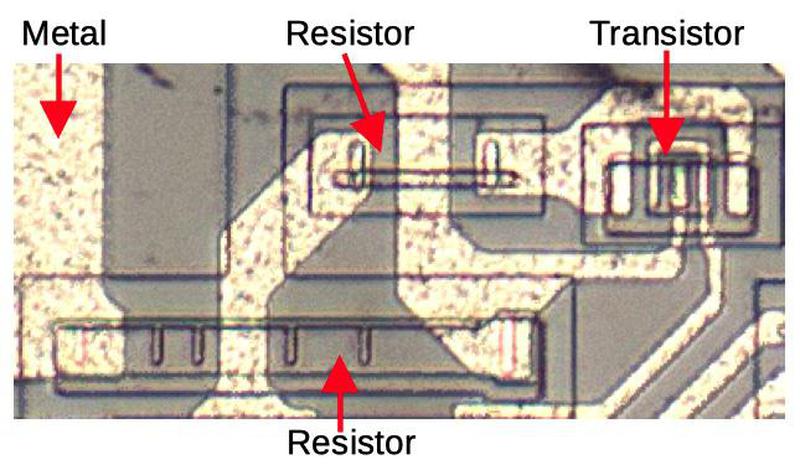

The diagram below is a detail from the chip, showing two types of resistors and a transistor. The upper resistor above is made from a line of higher-resistance N-type silicon, with metal contacts connected to either end. This forms a 65Ω resistor. The lower resistor has six contacts, providing multiple resistance values depending on where the metal lines are attached. It uses P-type silicon for the resistive element, providing hundreds of ohms of resistance. (There's a bit more internal structure to the resistors, but I'll ignore it.)

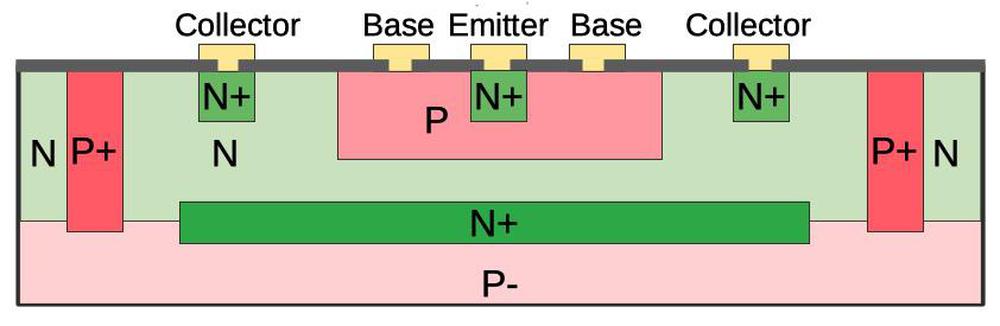

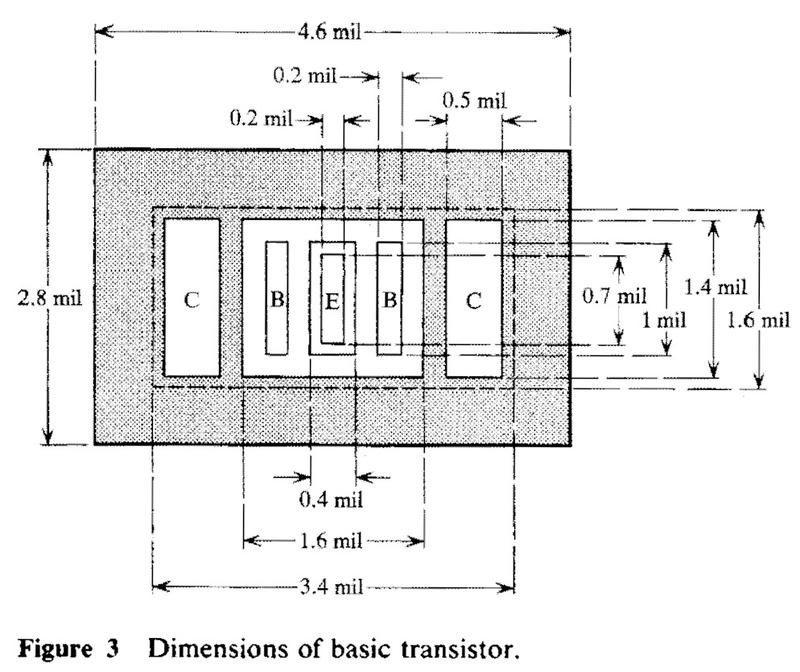

The transistors are bipolar NPN transistors, but their structure is a bit more complex than the typical NPN transistor. Physically, they have two bases and two collectors wired together to reduce current density, so you'll see five metal connections to each transistor. The diagram below shows the cross-section structure of the transistor. The five metal connections on top of the cross-section correspond to the five connections on the transistor above. The collector, base, and emitter are connected to N-P-N layers, forming the NPN transistor.9 The P+ ring provides isolation around the transistor.

By recognizing the components on the die and tracing out the wiring, the circuit can be reverse-engineered. However, if you look at the die closely, you'll see that many components are not connected. The reason is that IBM used a technique called "master slice" to produce a variety of integrated circuits without custom-designing each one.10 The idea was to use a common silicon die with multiple transistors and resistors. By modifying the metal layer (which was relatively inexpensive), the components could be wired into the desired circuits. This is also why the resistors had multiple taps, so they could be wired to obtain different values as needed.

The differential amplifier and ECL logic

Logic circuits can be built in a wide variety of ways. Almost all computers today use a logic family called CMOS (complementary metal-oxide-semiconductor), building gates out of MOS transistors. However, the IBM System/370 used a high-performance11 logic family known as Emitter-coupled logic (ECL), which IBM called Current-Switch Emitter Follower (CSEF).12 ECL was invented at IBM in 1956 for use in IBM's high-performance transistorized computers.

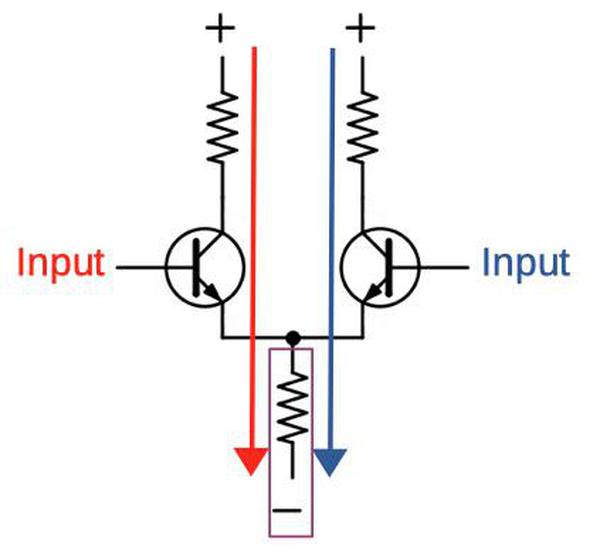

ECL is based on a differential pair, a circuit that amplifies the difference between two inputs. (This circuit is also the basis of op-amps.) The idea behind a differential pair (below) is that a fixed current flows through the circuit. If the left input is a higher voltage than the right, the left transistor will turn on and most current will flow through the left branch (red). Conversely, if the right input is a higher voltage than the left, the right transistor will turn on and most current will flow through the right branch (blue). The differential pair provides amplification because a small difference in the inputs will create a large shift in the current.

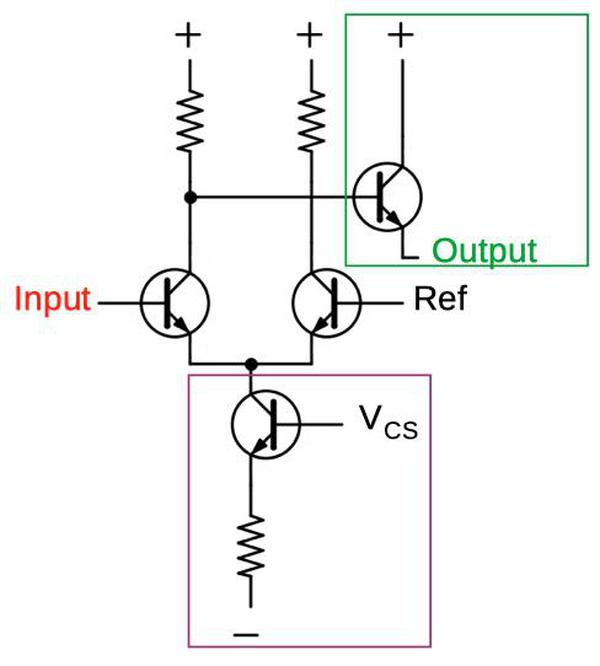

The above circuit is used as an amplifier in the chip, but with a few modifications it also forms an ECL gate. For a gate, the voltage into one branch is fixed at a reference voltage, midway between the "0" level and the "1" level. Thus, if the input is higher than the reference voltage, it will be considered a "1", and lower will be a "0". (MST chips used ground as the reference voltage.4) The ECL circuit below is an inverter, since if the input is high, the current through the left resistor will pull the output low. To improve performance, the bottom resistor has been replaced with a current sink circuit (purple). The current through the current sink is set by an external bias voltage (VCS).

A buffer (green) has been added to the output above. The buffer circuit is called an emitter follower since the output is taken from the transistor's emitter and the output follows the input. This is why IBM used the name Current-Switch Emitter Follower for this logic family.

The sense amplifier chip's circuitry

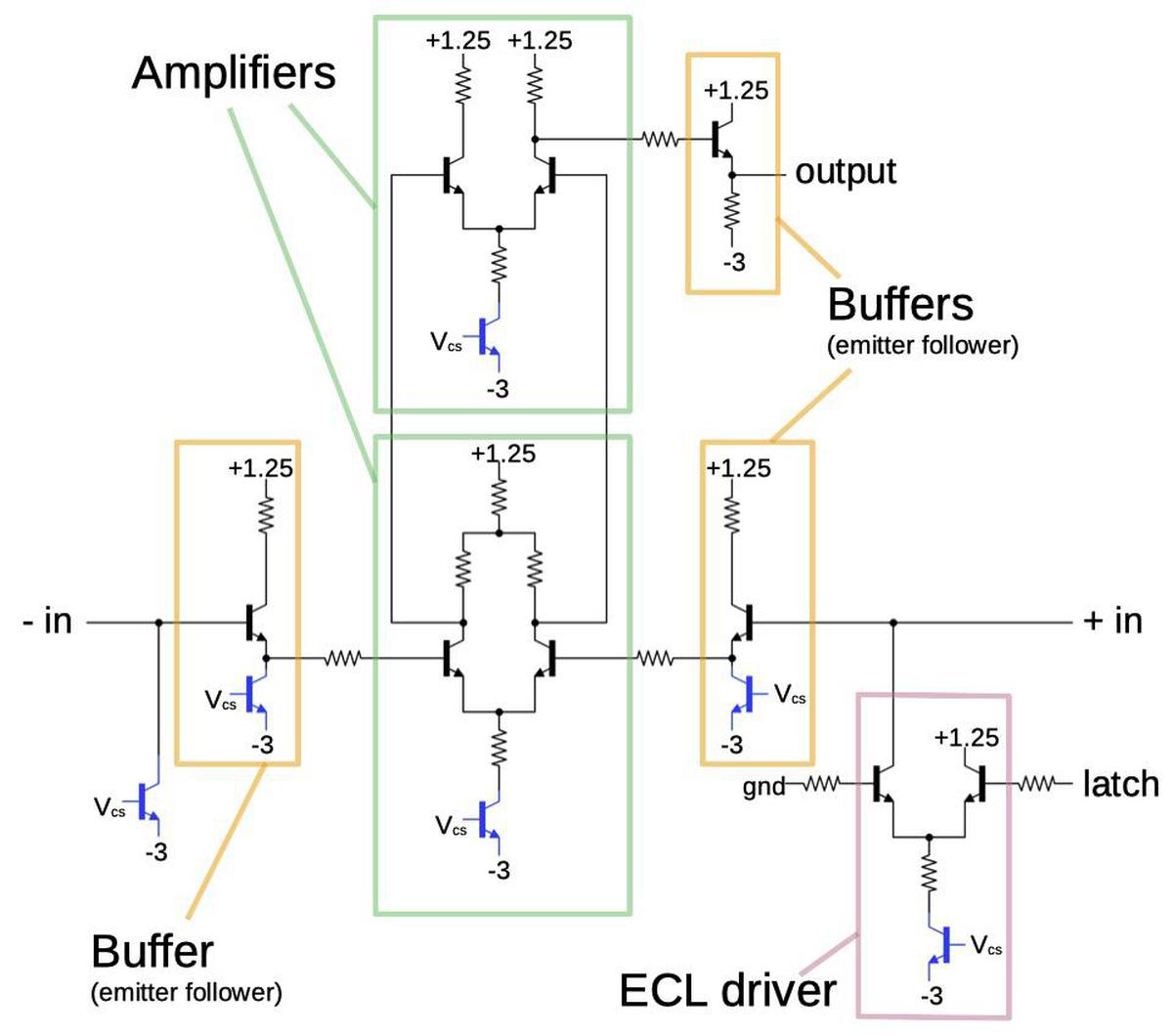

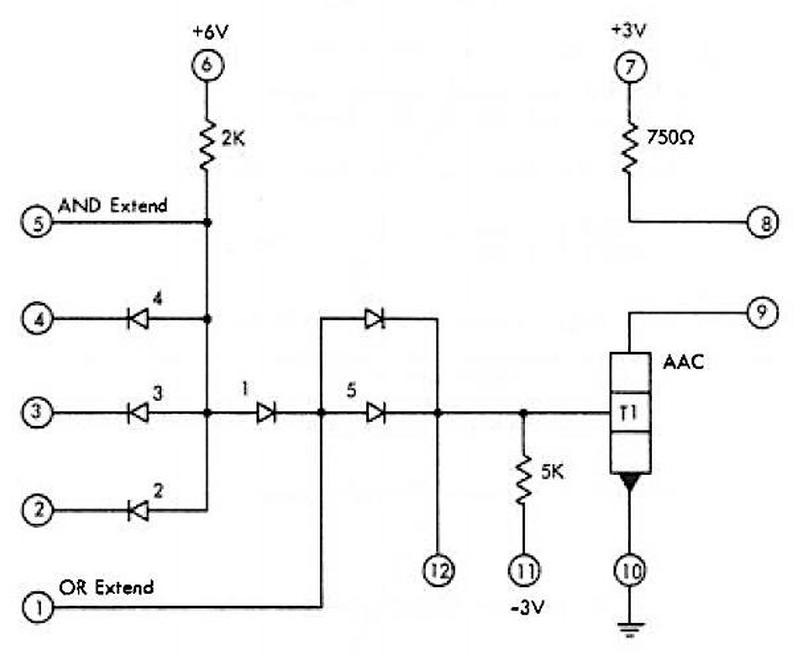

I reverse-engineered the chip's circuitry and found it contains two copies of the circuit below. This circuit is a differential amplifier, probably used as a sense amplifier to amplify the outputs from the memory chip and convert them to logic signals.13

The chip takes two inputs, a negative input and a positive input, and produces a logic-level output. The circuit is a bit complicated, but I'll try to explain the highlights. The differential amplifiers (discussed earlier) are the core of the chip. The input signals are buffered and then go into the lower amplifier (green box). The outputs from that amplifier go into the upper amplifier. Cascading two amplifier stages in this way makes the chip very sensitive, providing a large degree of amplification.

The yellow boxes are buffers, using the emitter-follower circuit described earlier. One buffer is used on each input and one on the output. The purple box is an ECL gate. I believe it is used to latch the amplifier's value by feeding the output back in. The current sink transistors are colored blue to distinguish them. They provide a constant current to the differential amplifiers and other circuits.

Conclusion

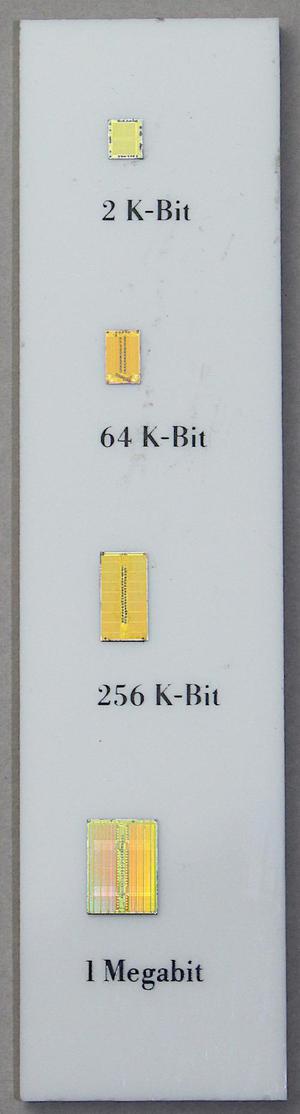

Well, this is a lot of analysis for a paperweight. But this paperweight provides an interesting window into IBM's technology of 1974.14 In particular, it illustrates IBM's transition to integrated circuits and semiconductor memory for the System/370 mainframes. It also explains IBM's unique construction technique for integrated circuits, packaging them on a ceramic wafer in a square metal can, a technology they called MST. Finally, the paperweight's 1-kilobit memory chip shows the amazing progress that memory technology has made over the past decades, giving us megabit chips and now multi-gigabit chips.

Thanks to @magnetic_tape for sending me the paperweight. Thanks to Mark Smotherman for information on MST. I announce my latest blog posts on Twitter, so follow me @kenshirriff. I also have an RSS feed. If you're interested in old IBM technology, see my recent post on an IBM Technology Box, covering 1948 to 1986.

Notes and references

-

The text "Essones" on the paperweight refers to IBM's semiconductor plant in Corbeil-Essones, a suburb of Paris. IBM opened this plant in 1964, Europe's biggest semiconductor factory at the time. ↩

-

Curiously, one of the dies in the paperweight is damaged and has a corner missing. Note that it's not simply broken, since the metal layer and the silicon doping don't go to the edge. Probably this die is from the edge of the wafer so it didn't get fully exposed. With the incomplete wafer and the truncated die, it's clear that they were using junk parts in the paperweights.

One die in the paperweight is damaged. -

For a while, IBM used a rational numbering system for the System/370 models, with computer power increasing with the model number. Model numbers ranged from the low-end Model 115 to the high-end Model 195. However, the numbering system fell apart in the late 1970s as systems were assigned seemingly-random numbers such as 3031, 4361, 3090, and 9370. Despite having the biggest number, the 9370 was a low-end machine. See IBM's 360 and Early 370 Systems for a detailed history of the System/370. ↩

-

IBM had multiple versions of MST logic for different products; some versions used different voltages. MST-1 uses ground as the upper voltage, -4 volts as the lower voltage, and -1.32 volts as the ECL reference voltage. (Because ECL circuits are more sensitive to fluctuations in the upper voltage, ECL families often assign that level to ground, making the lower voltage negative.) MST-2 shifts the levels so the reference level is ground; the upper voltage is +1.25V and the lower is -3V.

I couldn't find much information on the other MST variants, but for reference I'll summarize what I did find. MST-2 was used in the S/370 Models 145 and 155, while MST-4 was a high-performance version developed by Texas Instruments and used in the S/360 Model 85. The S/370 Model 168 used MST-1, MST-2, MST-4, and MST-A. The System/3 used MST-10. The IBM 3889 OCR machine, 3350 Disk Storage, and 3704 Communications Controller used MST-1 and MST-E. The IBM 3031 used MST-1, MST-2, MST-4, MST-4E, MST-E, and MST-A. Other versions included MST-195 and MST-255. ↩↩

-

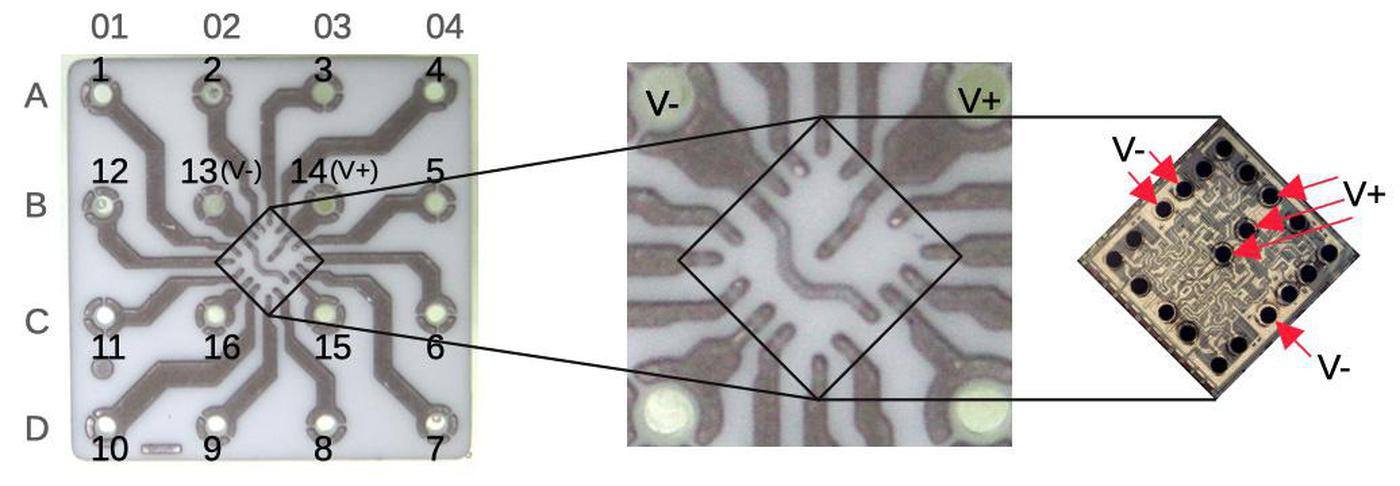

The MST ceramic substrate provides the interface between two circuitry scales: the printed circuit board scale with 0.125-inch pin spacing, and the integrated circuit scale with 0.01-inch solder ball spacing. The pattern on the MST ceramic substrate has some interesting subtleties; each power pin is connected to three solder balls, allowing more current into the IC. The trace for V- crosses the chip, providing two connections on one side and on on the other. The trace for V+ extends into the middle of the IC to provide additional power connections.

Diagram showing how the chip is mounted on the ceramic substrate. (The chip image has been mirrored to account for it being mounted upside down.)For some reason, MST uses two different pin-numbering schemes. The 12-pin SLT numbering was extended by spiraling 13-16 into the middle. But the more common MST pin names are A01 through D04.

-

IBM called the chip mounting technique "controlled-collapse chip connections" or C-4. It used a controlled volume of solder to make electrical and mechanical contact with the module. During soldering, the chip was pulled into alignment with the module fingers by surface tension, similar to how a surface-mount device is soldered today. For more details, see Design of Logic Circuit Technology for IBM System/370 Models 145 and 155. ↩

-

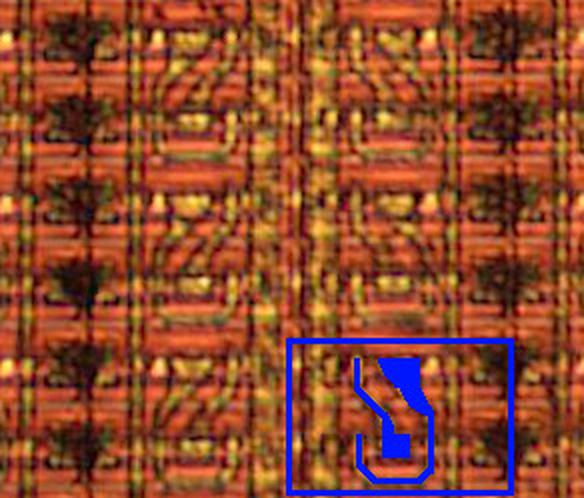

The photo below is the best resolution I could get of the memory cells. I believe this is six memory cells; I put a box around one. The circuitry in two rows is connected as shown in blue. This is probably two cross-coupled inverters, a standard circuit for a static RAM cell.

Closeup of six memory cells in the memory chip. -

The diagram below provides more details on the construction and dimensions of the transistors.

The transistors in the MST chips have a single base and collector but has two base and collector connections to reduce current density. Image from Design of Logic Circuit Technology for IBM System/370 Models 145 and 155. -

The master slice approach used a fixed silicon layout with transistors and resistors, but changed the metal interconnections to create different chips, a process called "personalization". The diagram below, from patent 3539876, shows a silicon layout used for IBM's master slice integrated circuits. If you match up the resistors and transistors, this diagram is almost identical to the die in the paperweight. There are a few differences, though. In particular, the die has an extra pin on the left and right, with slight resistor changes to accommodate them. Design of Monolithic Circuit Chips (1966) describes the origins of the master slice approach. Even in 1966, they were using computer-assisted design for integrated circuits.

The die structure from patent 3539876 is almost identical to the chip. -

ECL gates obtained much of their speed advantage because the transistors were not completely turned on (i.e. saturated). This allowed the transistors to switch the current path rapidly. Additionally, the difference between a "0" voltage and a "1" voltage was small (about 0.8) volts, so signals could switch between the two voltages quickly. In comparison, TTL gates typically had a difference of about 3.2 volts between a "0" and a "1", requiring more time to switch. (Signals could typically switch at about 1 volt per nanosecond, so a larger voltage swing caused nanoseconds of delay.) On the other hand, the small voltage swings of ECL made the circuits more sensitive to electrical noise. ↩

-

For more details on ECL logic and how IBM used it, see Design of Logic Circuit Technology for IBM System/370 Models 145 and 155. ↩

-

I'm not completely sure of the role of this chip. I searched extensively, but couldn't find any documentation on it. IBM's MST modules are described in detail in MST-2 Module Data (1974). Inconveniently, the chip's part number (2551667) doesn't appear in this document (although nearby part numbers such as 2551665 are described). Thus, I had to study the circuit to determine its function. At first I expected it to be a standard logic gate. However, the two amplification stages didn't make sense, or the complementary inputs. Another possibility was that it converted differential signals (such as from the Differential Current Switch logic family) into ECL signals. That would explain the differential inputs, but not the two stages of amplification.

I think it's most likely that the chip is acting as a sense amplifier for memory chip, amplifying the memory chip's output and turning it into a logic level. The 370 Model 45 hardware manual (page 3-9) describes a sense latch module used with its memory, so external sense amplifiers were used in System/370. The chip pin that I've labeled "latch" may be used to feed back the output to latch it, or it may be used as an enable pin or to reset the latch; without seeing the surrounding circuitry, I'm not sure.

Intel also produced memory chips that required external sense amplifiers; see the Intel 1103 and Intel 2105. Intel produced sense amplifier chips, the 3208 and 3408 Hex Sense Amplifiers specifically to provide external sense amplifies for memory. One motivation for external sense amplifiers was that memory chips were built with MOSFET transistors, but bipolar transistors produced better amplifiers. Later memory chips, though, included the sense amplifiers on the chip. ↩

-

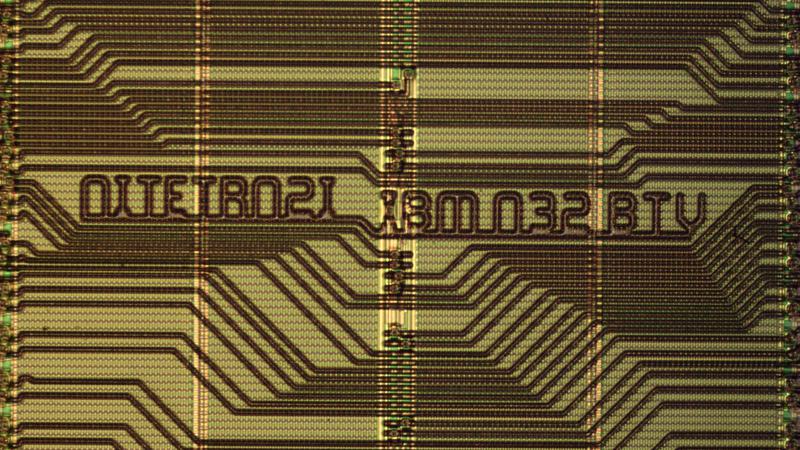

I'm guessing that the module is from 1974. Based on the technology, the paperweight is from the early 1970s. The module is labeled with the code "1 425C404". My theory is that the second digit "4" indicates the year, dating the module to 1974. IBM's modules are usually labeled with three lines of text, but there's no solid information on the meanings. The first line is the part number. The second line is believed to indicate the manufacturing location. (So "IBM 52" would indicate Essones, France. Although a reader tells me that IBM 52 was Poughkeepsie or Fishkill NY, while IBM 29 was Essex.) The third line is believed to be a date/lot code. Studying an extensive collection of cards, the digit after the 1 appears to be the year. For instance, some codes start with "1712" for 1977, "1 949" and "1925" for 1979, "1-005" and "1 031" for 1980, "1-106" for 1981, "1 205" for 1982, "1 444" for 1984, "1 865" for 1988, "1912" for 1989. But other modules have codes starting with "1 E52", "1 F09", and "1 H27" so it's not quite that simple. There also are a few codes like "1 8450" for 1984, suggesting they also used 2-digit year codes. It's possible that different sites used different codes. ↩