The Apollo missions to the Moon required complex hardware to communicate between Earth and the spacecraft, sending radio signals over hundreds of thousands of miles. The premodulation processor was a key component of this system, combining voice, scientific data, TV, and telemetry for transmission to Earth.1 It was built from components that were welded together and tightly packed into a 14.5-pound box.2 In this blog post, I look inside the premodulation processor, examine its construction, and describe how each module worked.

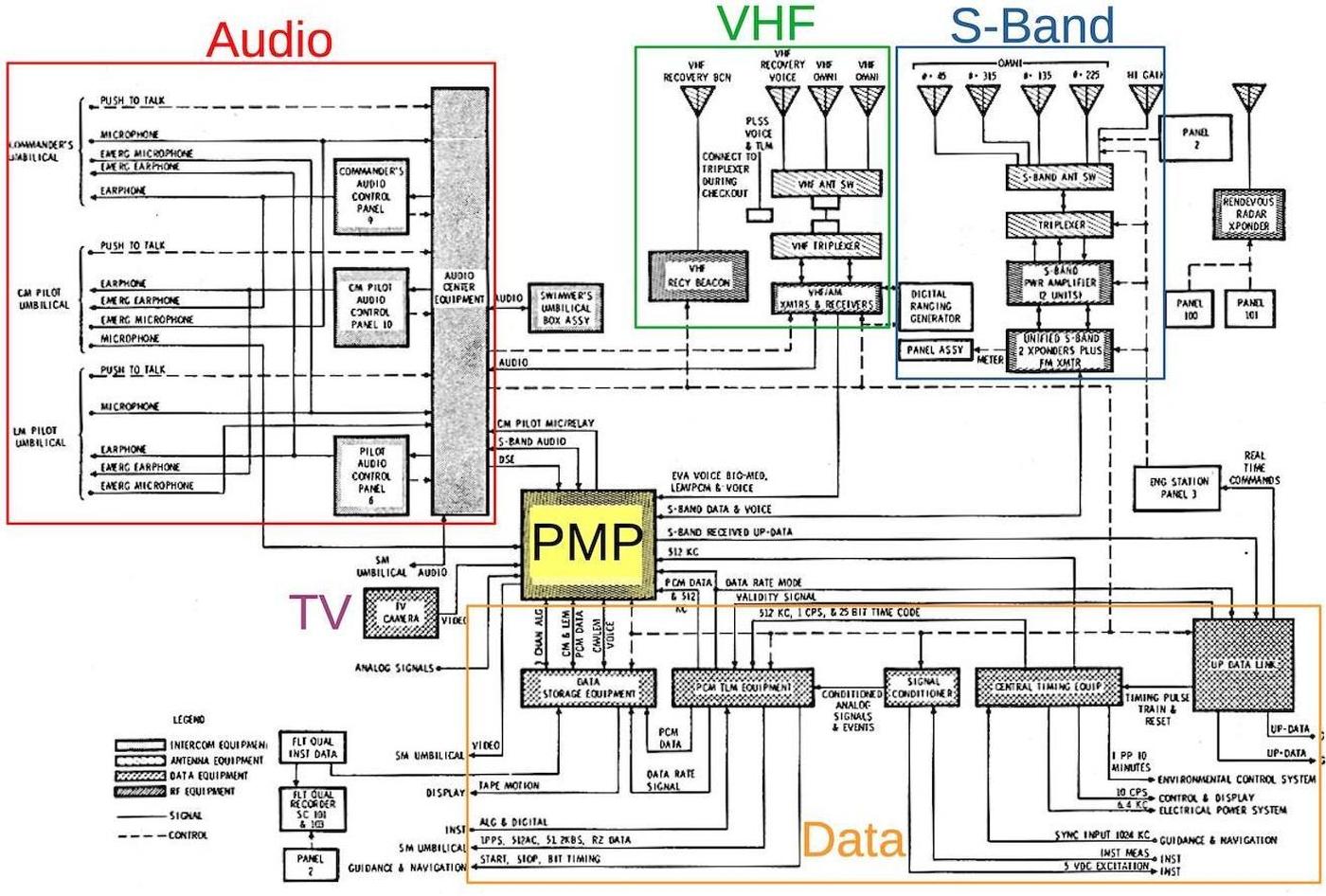

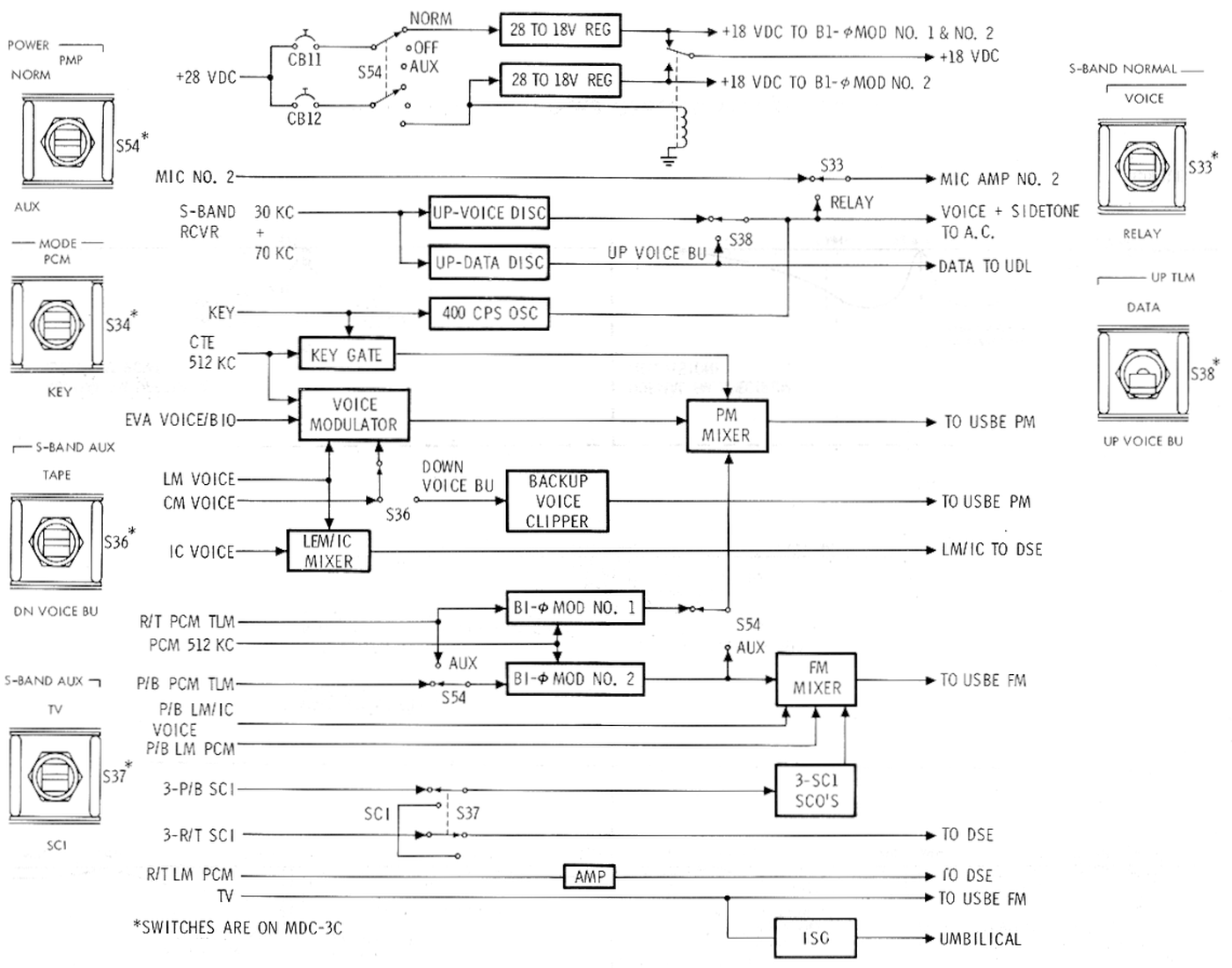

The communications systems in the Apollo Command Module were very complex, as shown in the block diagram below.3 The premodulation processor (PMP, yellow) played a central role: most of the audio (red), data (orange), and TV (purple) went through the premodulation processor, where the signals were combined for transmission by the S-band (blue) radio systems. The premodulation processor also handled most of the voice and data signals received from Earth or from the Lunar Module via the VHF (green) or S-band radio systems.

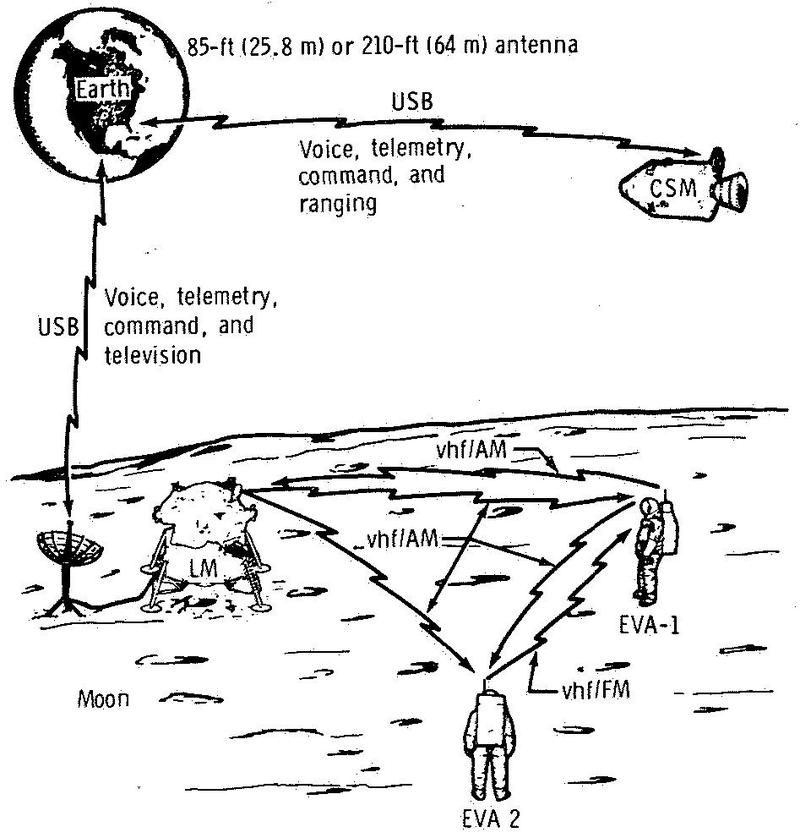

One reason for the complexity of the premodulation processor was that the audio system had to support a variety of communications configurations. The diagram below illustrates one configuration, when astronauts were walking on the Moon (i.e. extra-vehicular activity, EVA). They communicated with the Lunar Module on the Moon's surface via VHF/AM radio, which relayed their audio to Earth via the Unified S-Band (USB) radio. Meanwhile, the Command and Service Module (CSM) orbiting the Moon also communicated with Earth via S-Band. These voices were conferenced together so the astronauts and ground could all hear each other. The need for redundancy added to the complexity; for example, signals from the Moon could be relayed through the Command Module in the event of an equipment failure.

Construction

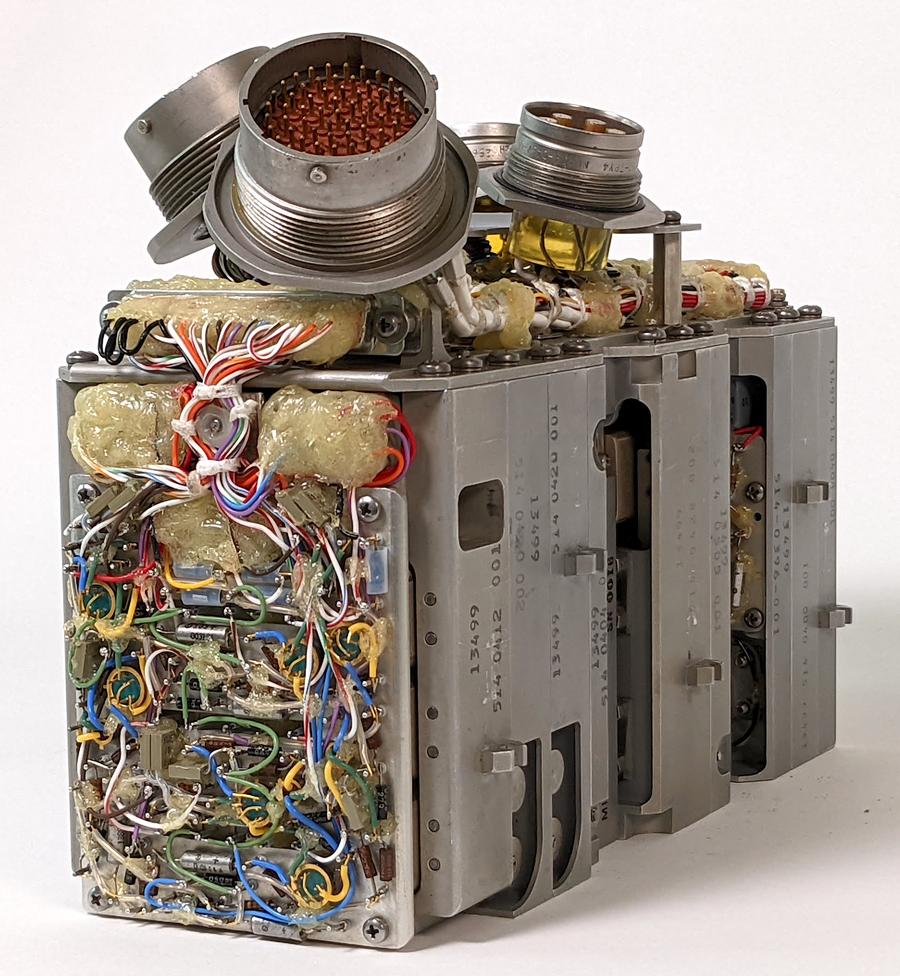

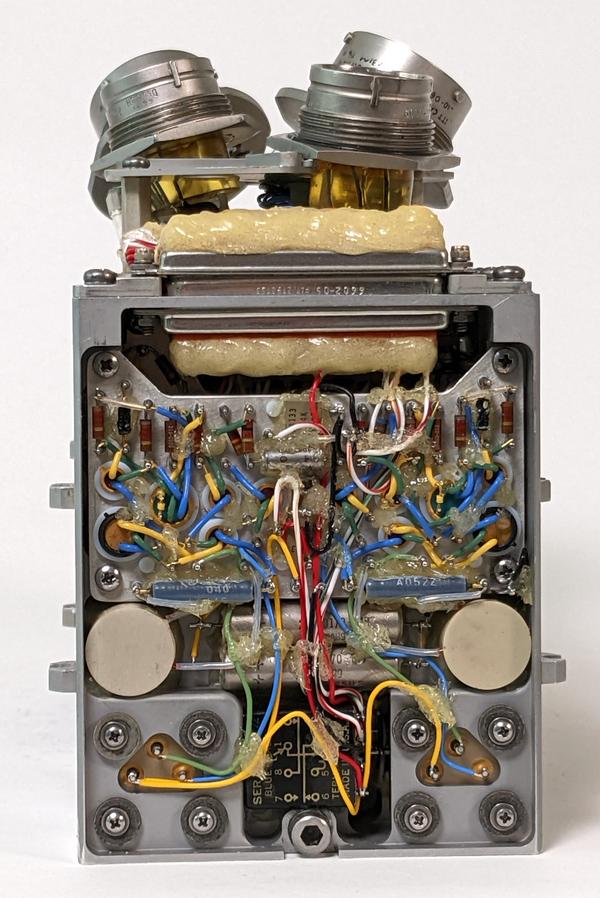

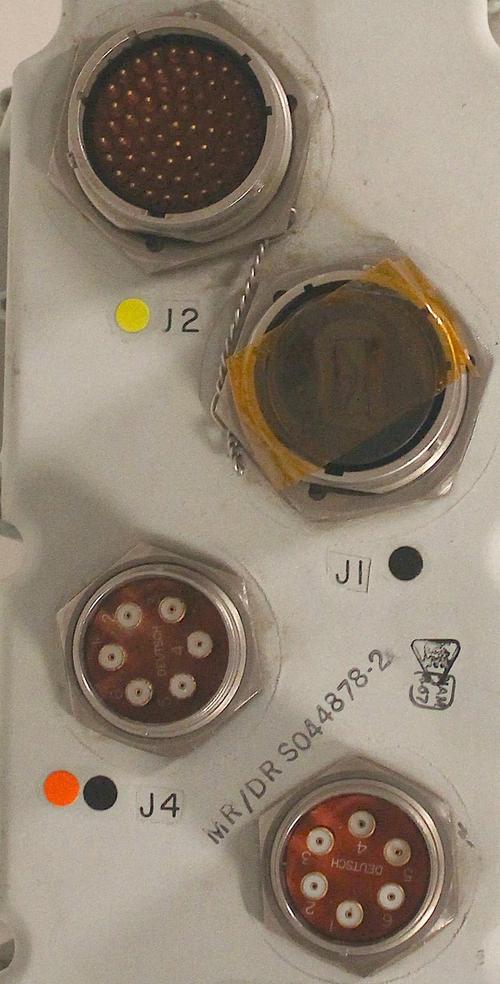

Like much of the Apollo electronics, the premodulation processor was packaged in a drab bluish metal case. The case has four round military-style connectors on top that linked the various audio, RF, and control signals to other components of the spacecraft.

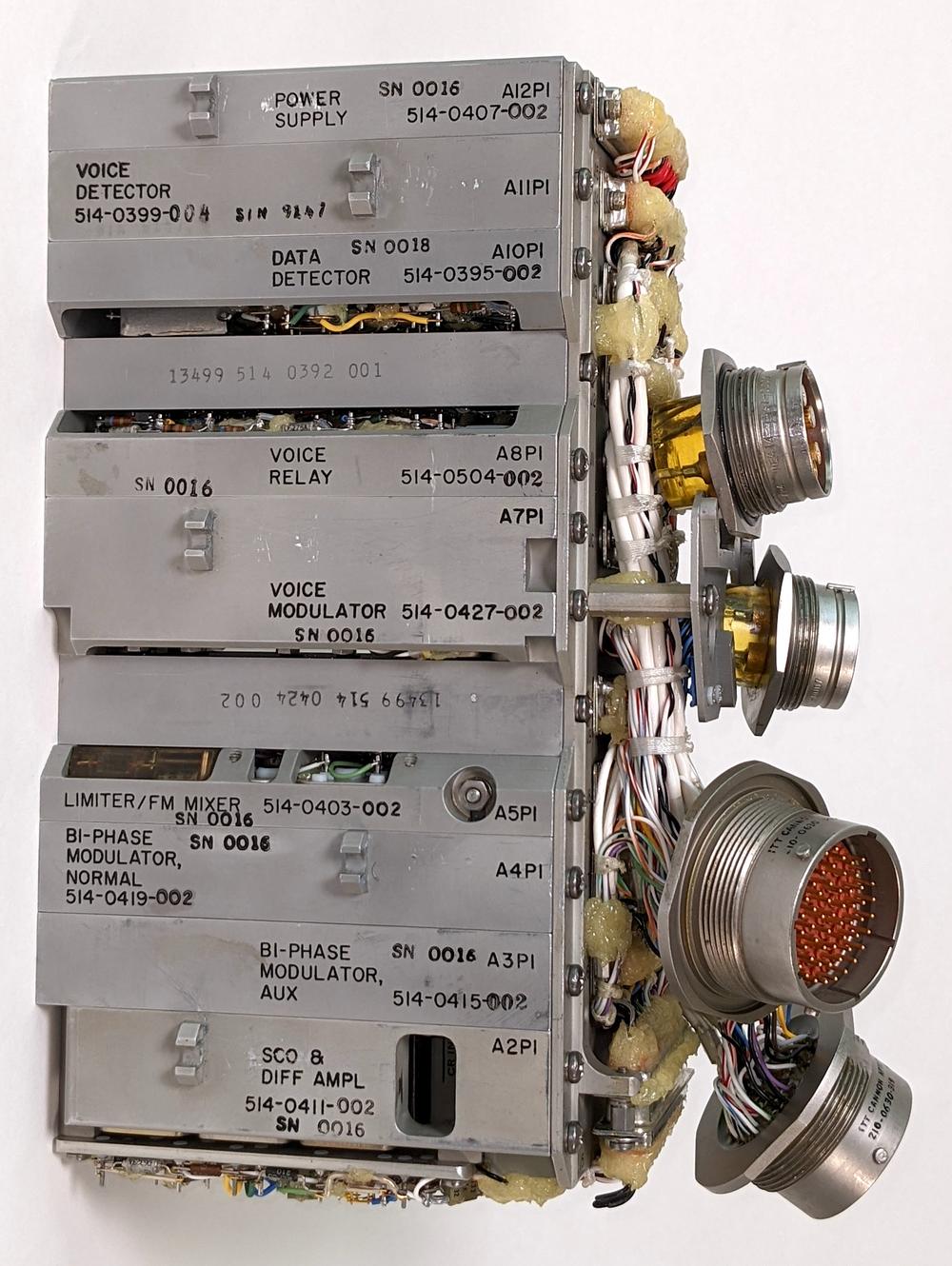

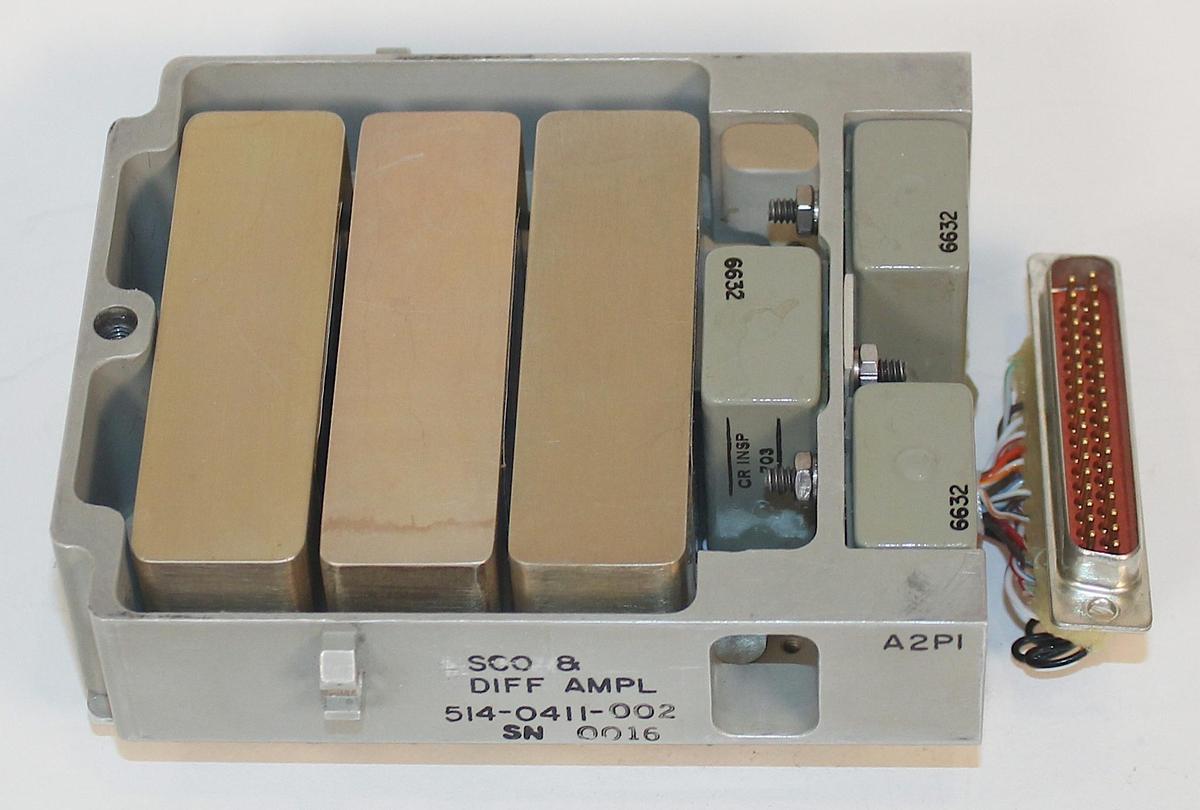

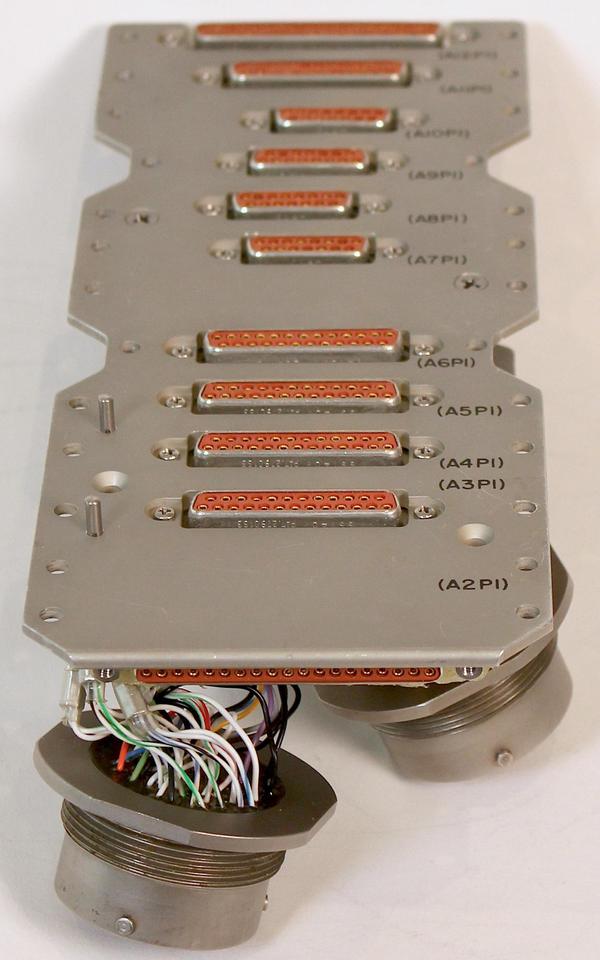

We opened the case by removing the screws and inside we found 11 rectangular modules packed together tightly, from the power supply at the top to the "SCO & diff ampl" (subcarrier oscillator and differential amplifier) at the bottom, conveniently labeled with their functions. The modules were plugged into a thin backplane,5 at the right, connected by D-Sub connectors, similar to vintage RS-232 connectors but in a variety of sizes. Bundles of wires connected the backplane to the round connectors. This construction technique made it easy for us to remove the modules and inspect them individually.

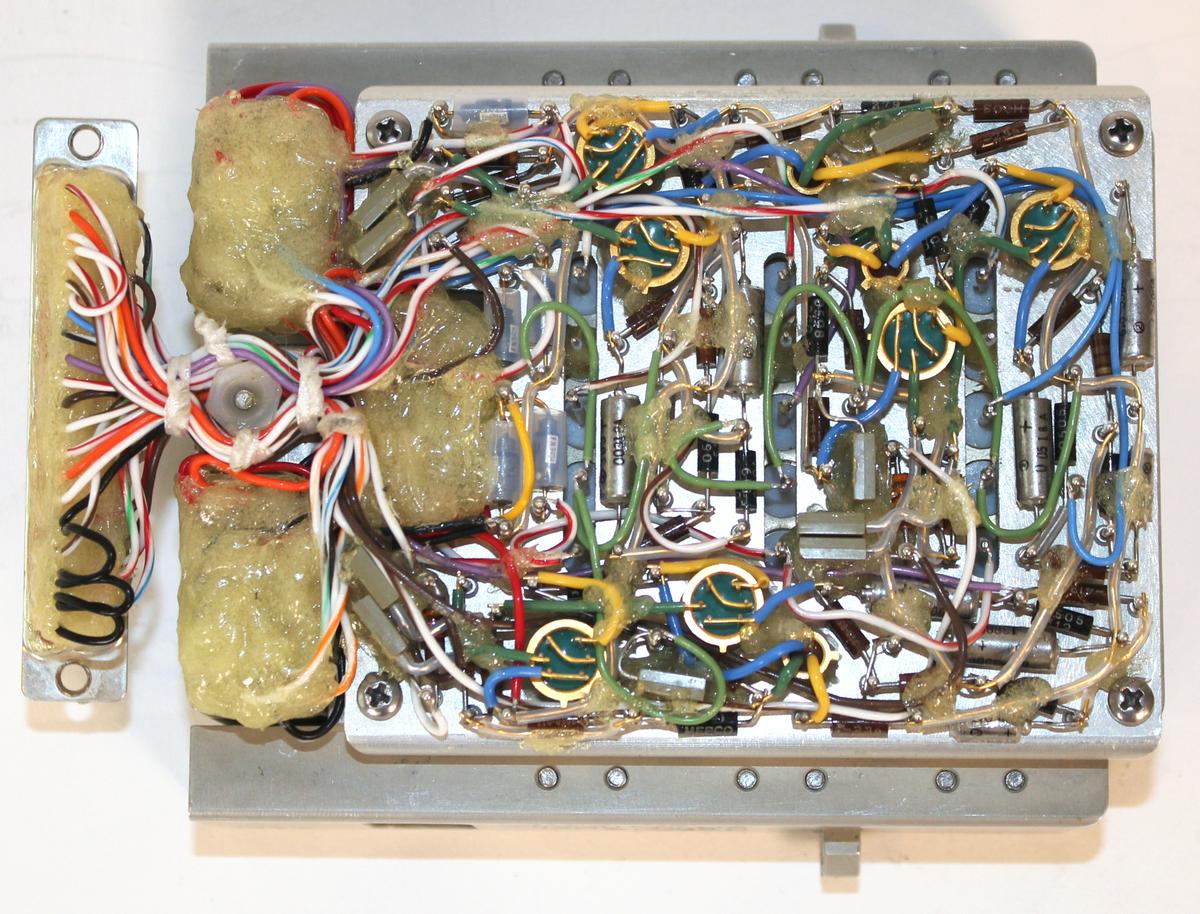

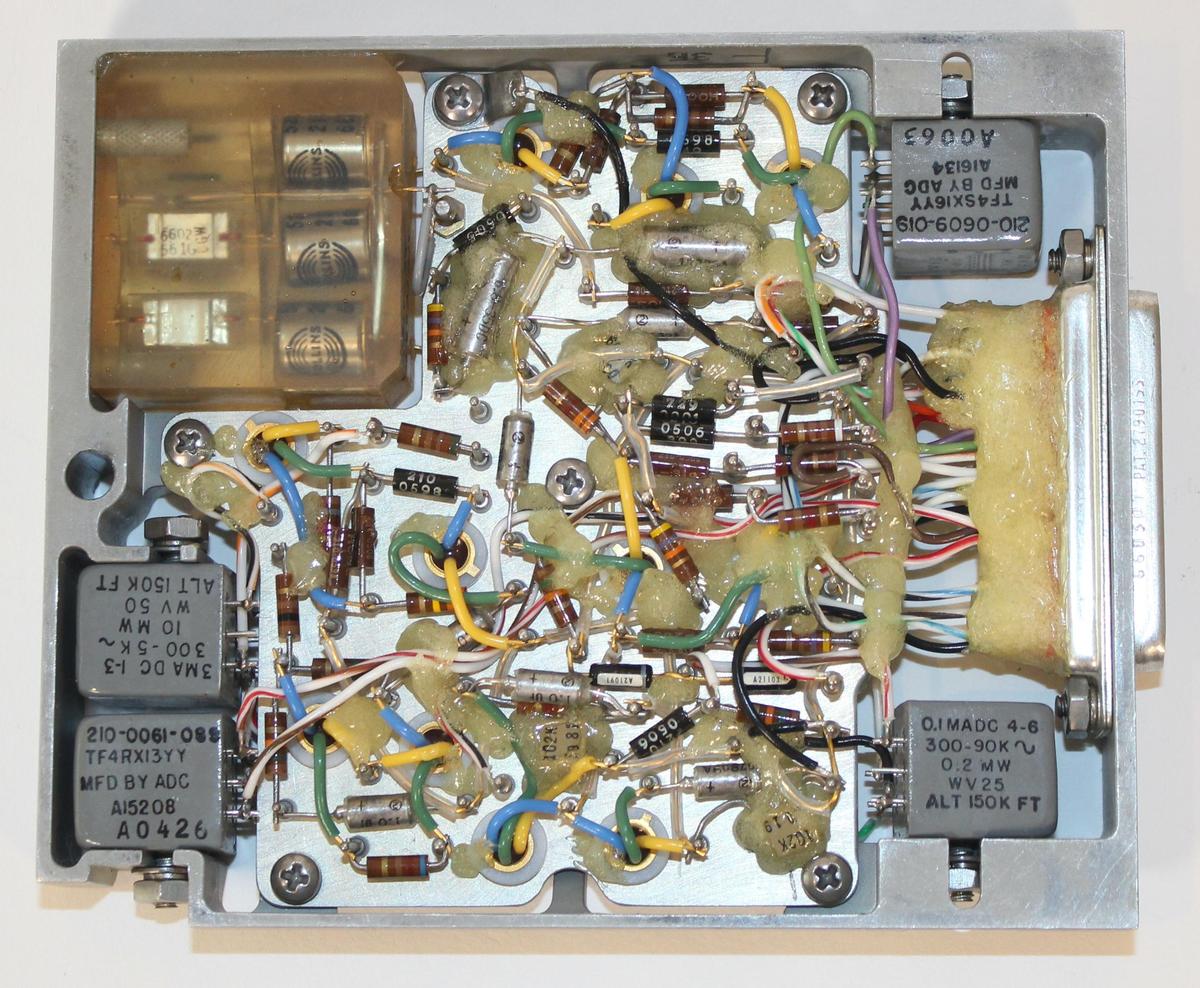

The modules themselves don't use printed-circuit boards, but instead are built from components that are spot-welded to metal pegs, as shown below.6 These resistors, diodes, capacitors, and transistors are tightly packed with a jumble of overlapping wiring. Most of the wiring consists of the component leads, but point-to-point wiring provided additional connection. The wiring is a combination of color-coded insulated wires, bare wires, and bare wires in clear insulating tubes. The components are liberally covered in what looks like hot glue. I suspect that the hot glue was only used in equipment for ground testing, while modules for spaceflight were fully encapsulated to prevent short circuits.

The modules have circuitry on both sides, which increased the density. About half of the metal pegs provide connection to the other side, while half have plastic stubs on one side. As will be seen below, many of the modules also contain rectangular metal sub-units that implement functional blocks such as oscillators or filters. It appears that these standardized functions could be bought "off-the-shelf", not as integrated circuits, but as blocks containing discrete components.

In the following sections, I'll discuss each module in more detail, starting with the power supply.

Power supply module

The premodulation processor contains a power supply that converted the spacecraft's 28-volt DC supply to 18 volts. For efficiency, it is a switching power supply, a buck converter that chops up the input power at a high frequency to drop it to the lower voltage. Although switching power supplies are now ubiquitous, in everything from phone chargers to PC power supplies, switching power supplies were expensive and rare in the 1960s, used in aerospace applications that required a compact, high-efficiency power supply.

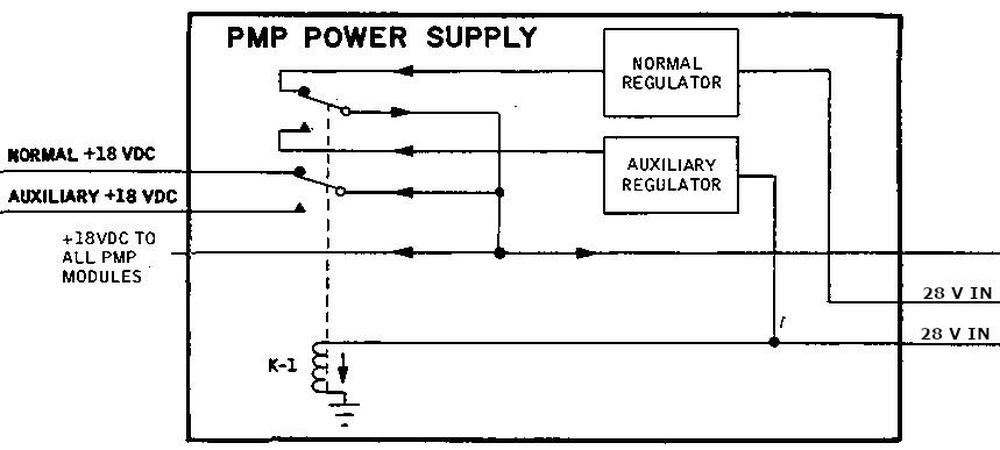

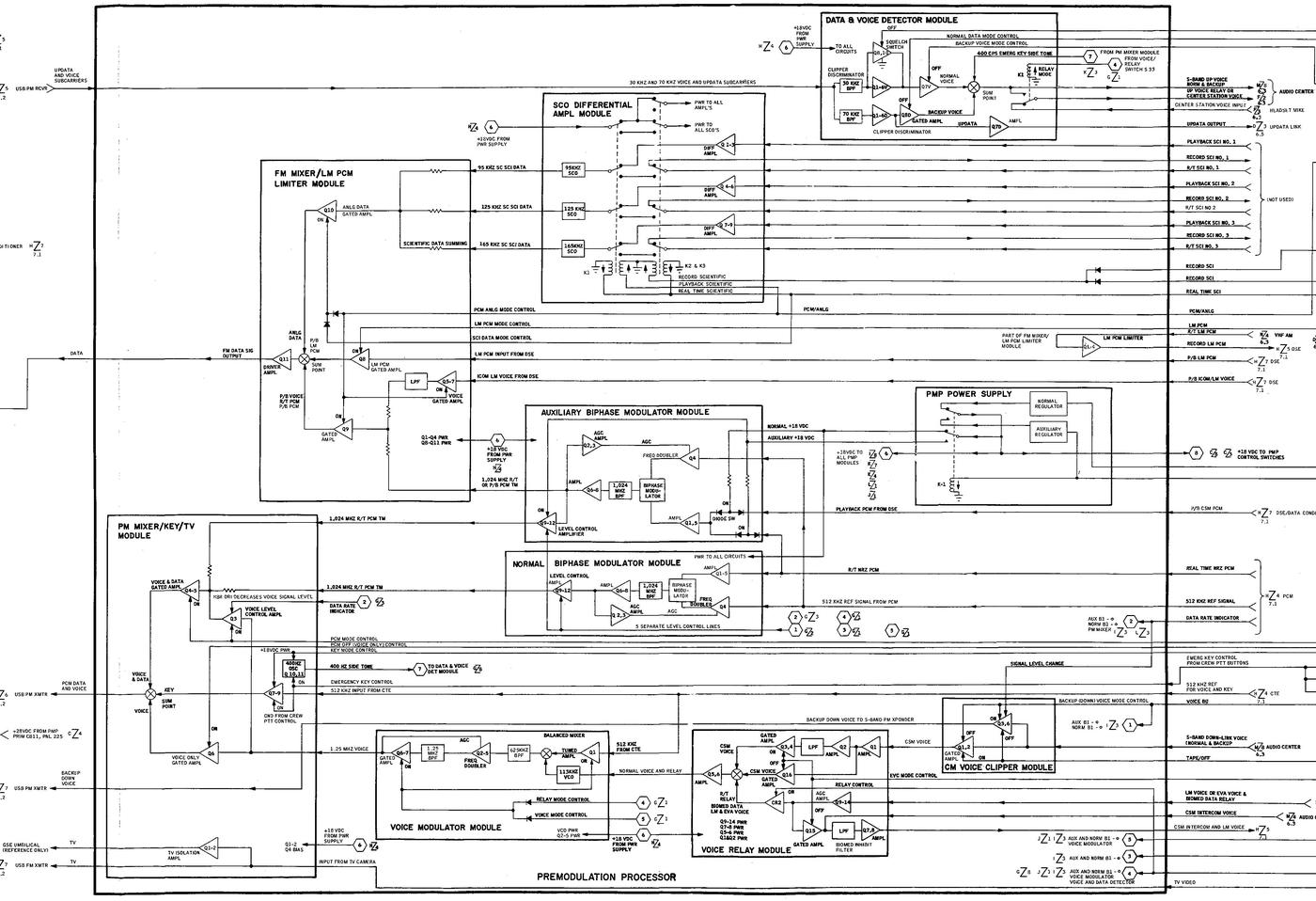

The block diagram below shows that the power supply was implemented redundantly, with a normal regular and an auxiliary regulator. A relay switches between the two regulators, controlled by the PMP NORM/AUX switch.

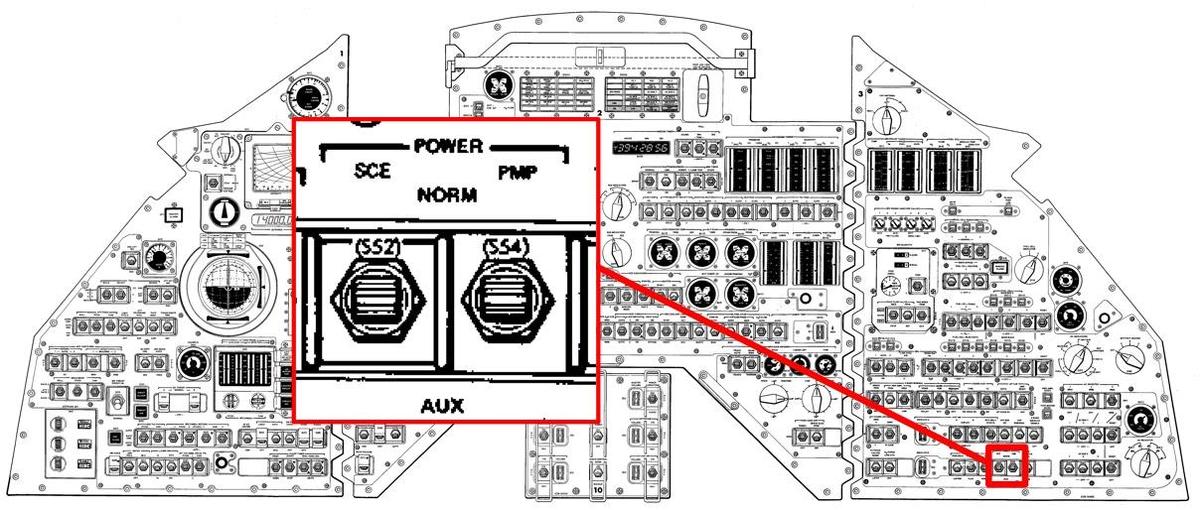

You may know of the Apollo 12 incident where the spacecraft was hit by lightning seconds after launch, scrambling the telemetry. The problem was resolved by the famous "set SCE to AUX" switch.7 The PMP's power switch is next to the SCE switch but never played a dramatic role.8

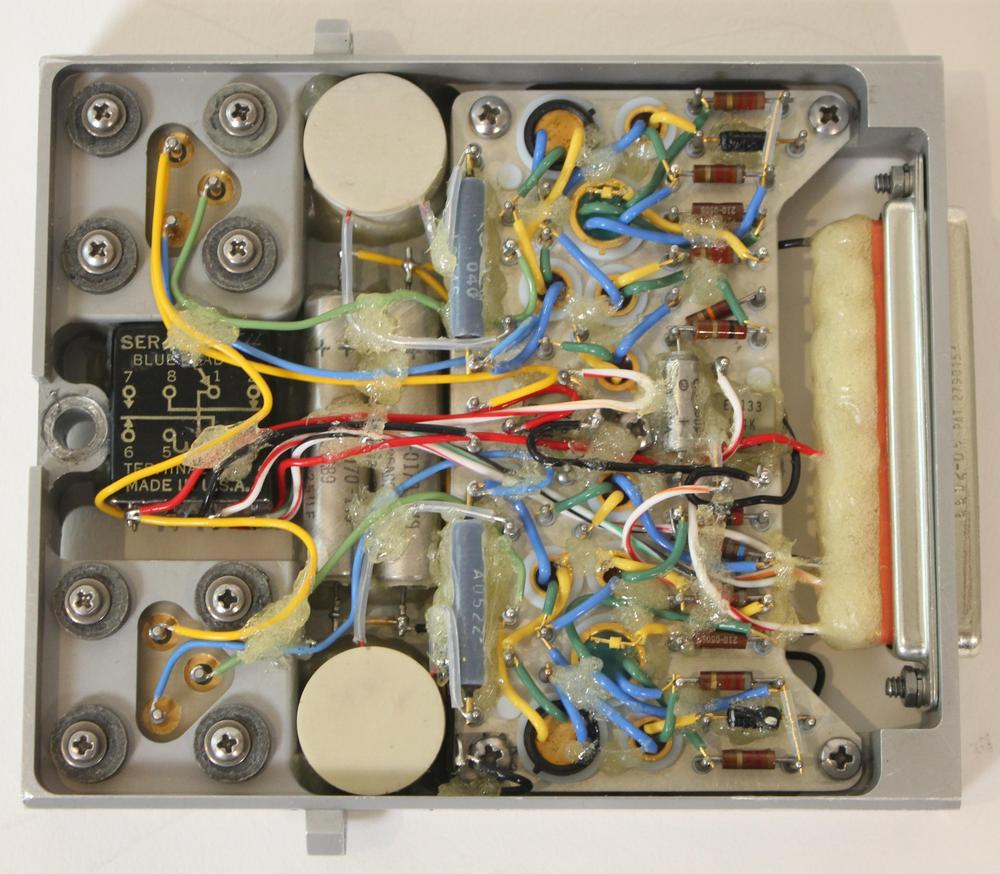

The photo below shows the power supply module. The redundant halves of the power supply are visible with the lower circuitry a mirror image of the upper circuitry. The relay to switch between the two is the black box in the center-left. The power switching transistors are above and below the relay, fastened down with screws. To the right of the transistors are cylindrical tan inductors, storing energy across each pulse. Large silver filter capacitors are between the inductors. The right half of the module is the control circuitry: resistors, capacitors, transistors, and diodes. The connector at the far right connects the power supply to the other modules via the backplane.

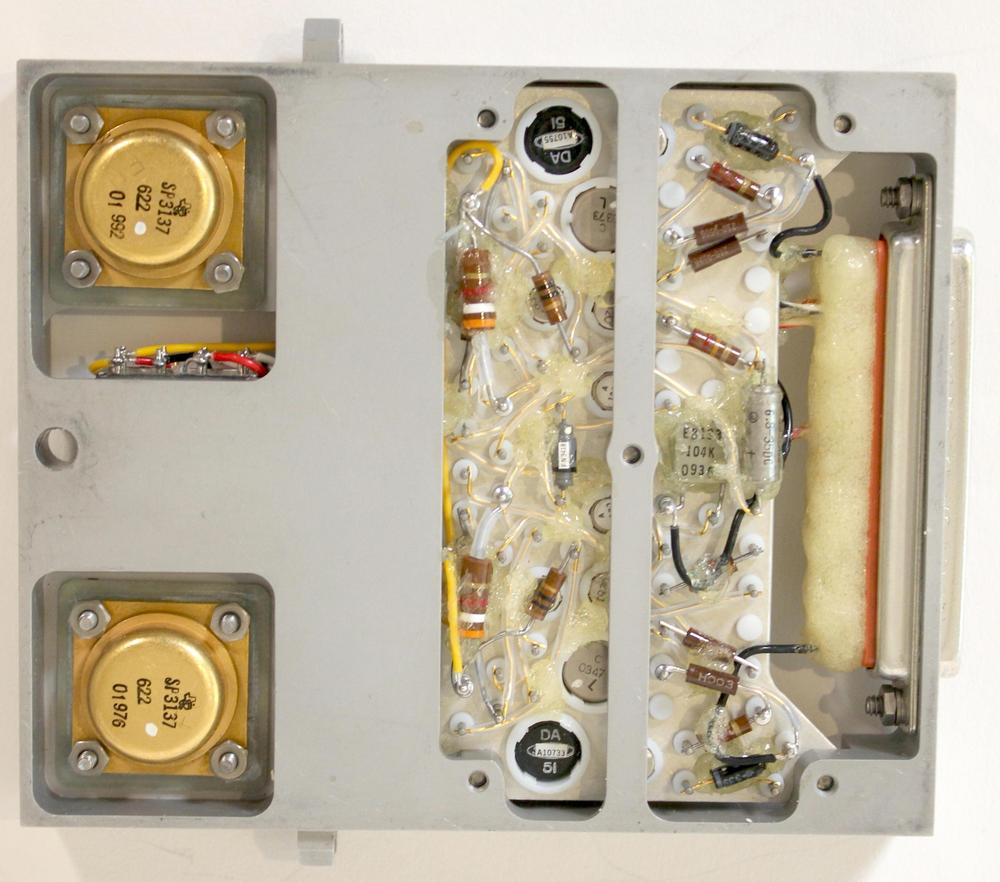

Flipping the power supply over reveals the high-frequency power transistors, in large metal packages to dissipate heat. These packages are square, unlike the typical two-tab (TO-3) power transistor packaging. Note the second layer of discrete component circuitry on this side of the module. This illustrates how the modules have two layers of circuitry, one on each side. You can also see the tops of the smaller transistors that are wired on the other side.

Voice and data detector module

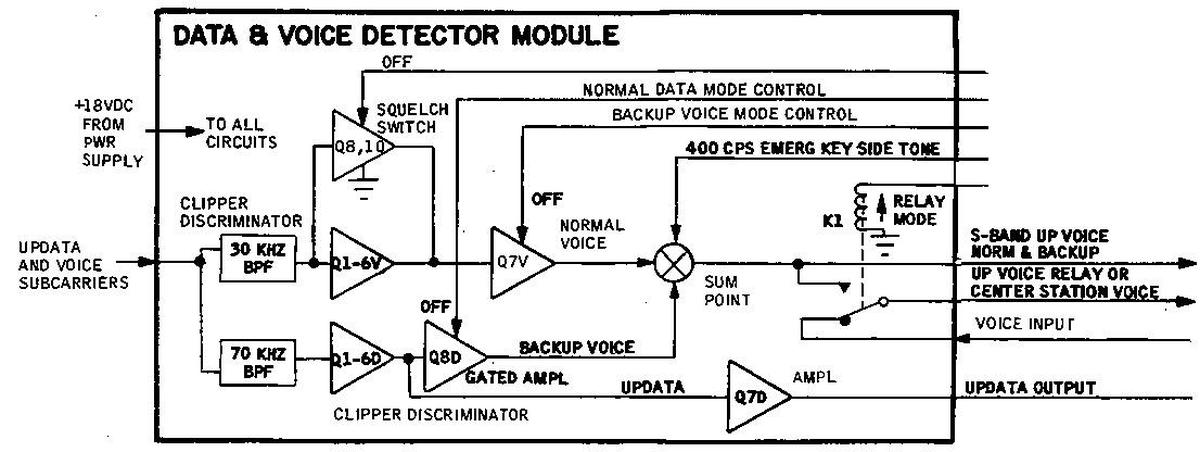

The data and voice detectors handle signals transmitted to the spacecraft over the S-band. The S-band transceiver receives these signals, demodulates them, and passes the signal to the premodulation processor. The data and voice detectors appear as one module on the block diagram below but are implemented as two modules physically.

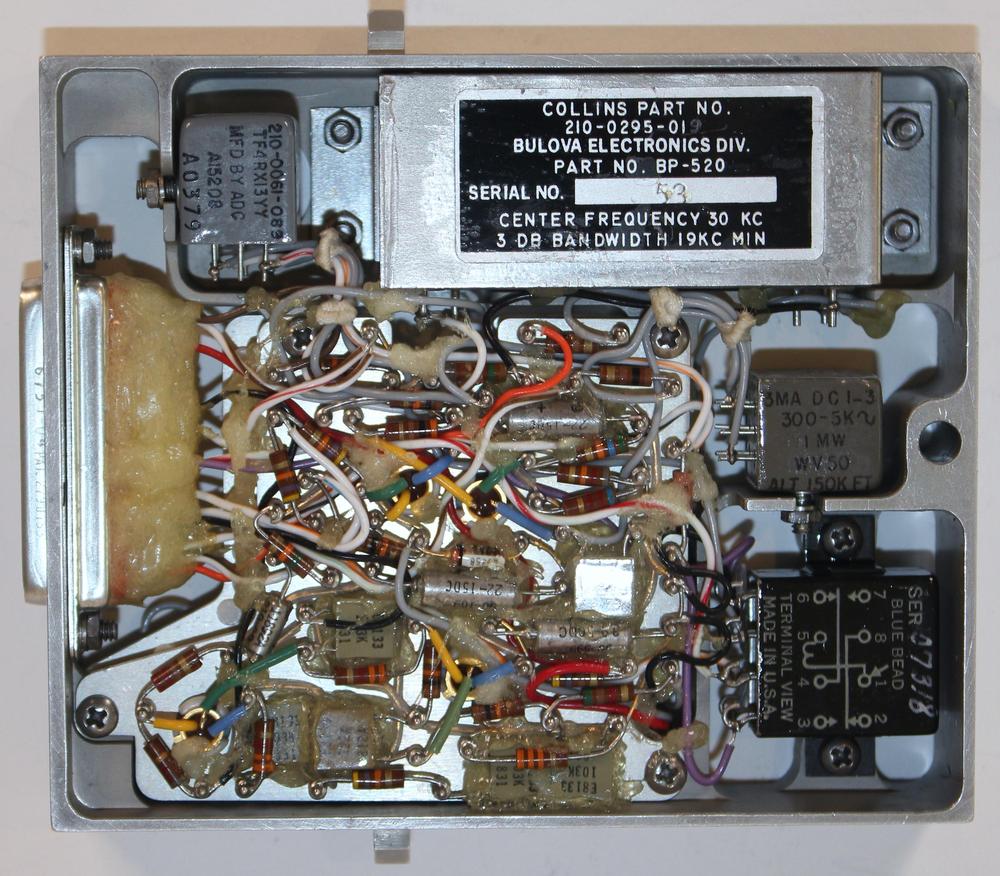

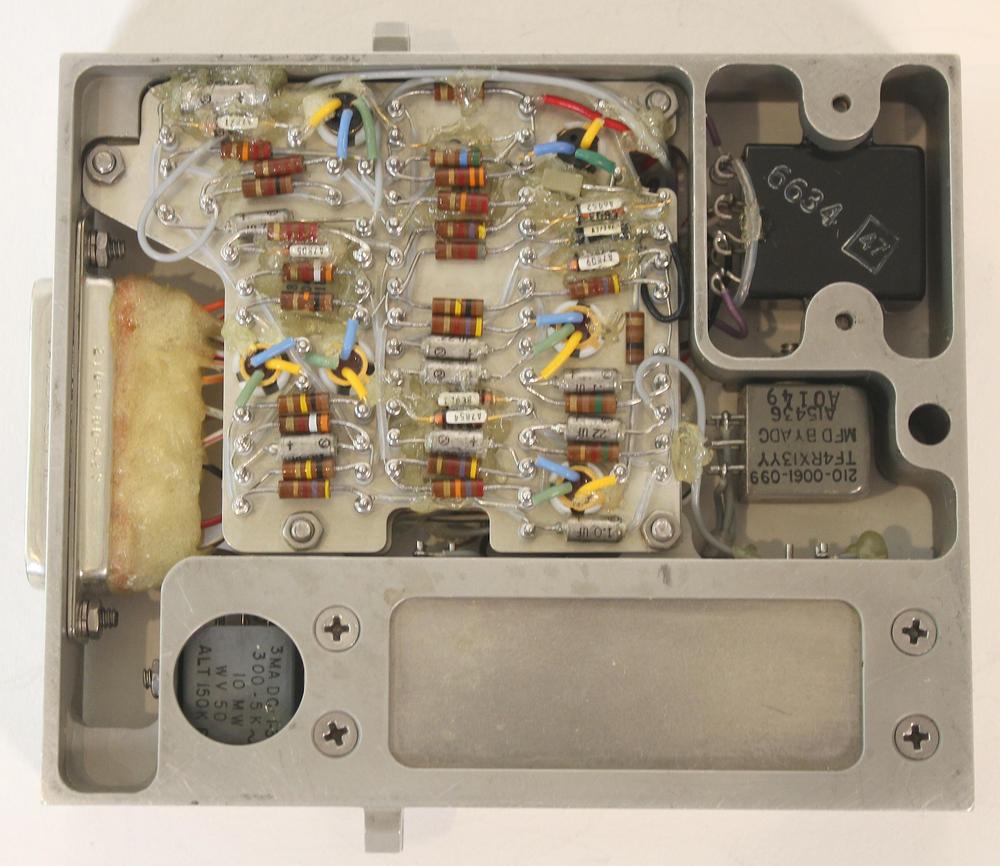

The photo below shows the voice detector module. Voice is transmitted to the spacecraft, frequency modulated onto a 30-kilohertz subcarrier. The voice detector extracts this signal through a 30-kilohertz bandpass filter, demodulates it with an FM discriminator, amplifies it, and sends it to the Audio Center, which provides it to the astronauts. The largest component of the module is the 30-kilohertz bandpass filter at the center top. This module was built by Bulova Electronics, a division of the watch company that produced quartz crystals, oscillators, filters, servo amplifiers, and other components. Two gray transformers are also visible; these coupled the audio signals. The black relay in the lower right was controlled by the "Up Voice Relay" console switch. (Don't be confused by the two completely different definitions of "relay".)

More circuitry is on the other side of the voice detector. The transformers, relay, and bandpass filter are visible through openings in the module's metal frame. The discrete components are arranged in orderly columns, unlike the other modules.

The data detector module operated similarly to the voice detector, except that it extracted the data link signals from ground. From the data detector module, data was processed by the Up-Data Link box, giving the ground control over multiple spacecraft systems. For instance, commands could be entered into the Apollo Guidance Computer. The spacecraft clock (CTE, Central Timing Equipment) could be set. Various relays could be controlled, overriding some of the switches on the console.

The implementation of the data detector module (above) is similar to the voice detector module, but simpler since it doesn't have the summing and switching circuitry. It uses a 70-kilohertz bandpass filter module, rather than the voice detector's 30-kilohertz filter. In case of a malfunction with the voice detector, backup voice communication could be transmitted to the spacecraft over the 70-kilohertz subcarrier, and extracted by the data detector module. This mode was controlled by the "Up-voice backup" switch.

Bi-phase modulator modules

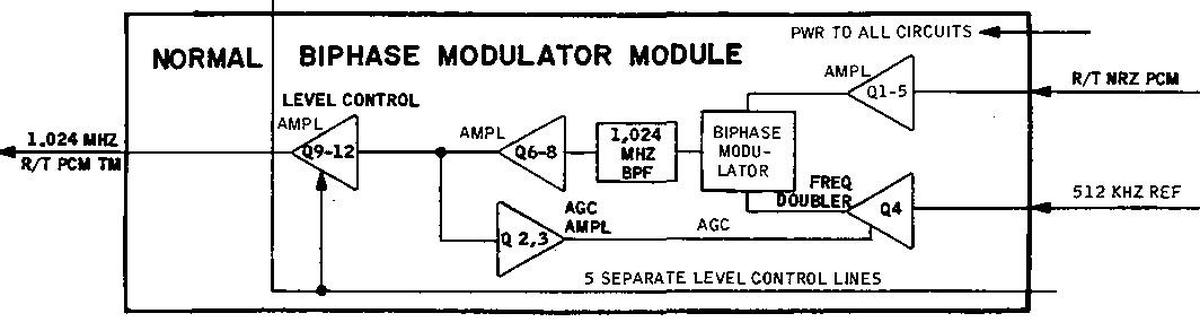

The role of the bi-phase modulator modules was to modulate telemetry data using bi-phase modulation. In total, data had three layers of modulation. First, data was digitally encoded using pulse-code modulation (PCM). Next, this module applied bi-phase modulation to the bits at 1.024 MHz. Finally, the S-band transceiver used FM or PM (frequency or phase modulation) for the communication to Earth.

Bi-phase modulation encodes a bit using a sine wave for a 1 and an inverted sine wave for a 0 (i.e. a phase shift of 180°). Bi-phase modulation is a type of phase-shift keying. The PCM data was at 51.2 kilobits per second ("high bit rate") or 1.6 kilobits per second ("low bit rate"). Since the data was modulated at 1.024 MHz, a bit was encoded by at least 20 cycles of the waveform. This gave the receiver plenty of time to determine the phase and distinguish a 0 from a 1.

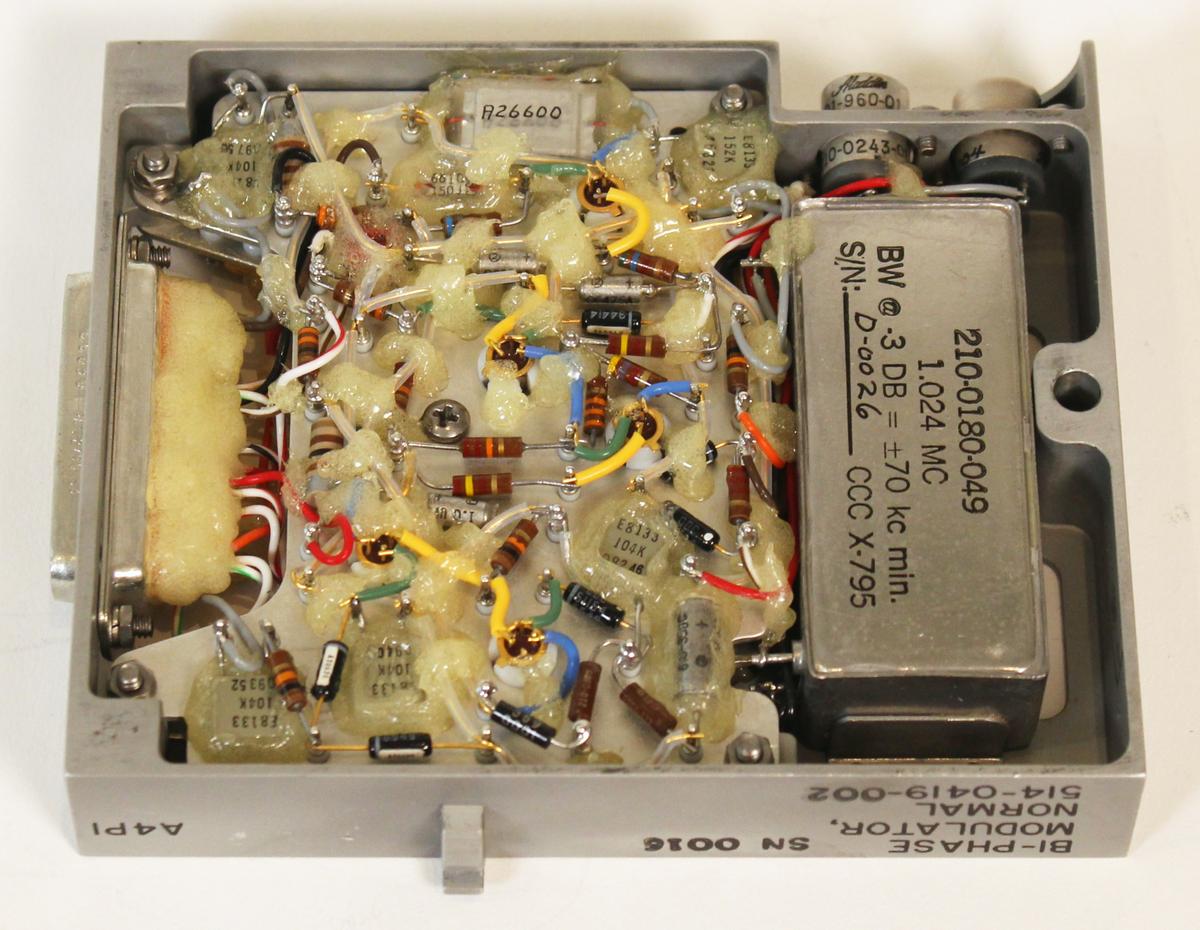

The premoduation processor contains two modulator modules: the "normal" module and the "auxiliary" module. The normal module transmits real-time data over PM, while the auxiliary module is more flexible. The normal bi-phase modulator module (below) contains a complex tangle of circuitry. The 1.024 MHz bandpass filter is the large metal package at the right, limiting the output signal to a narrow frequency range around 1.024 Mhz.

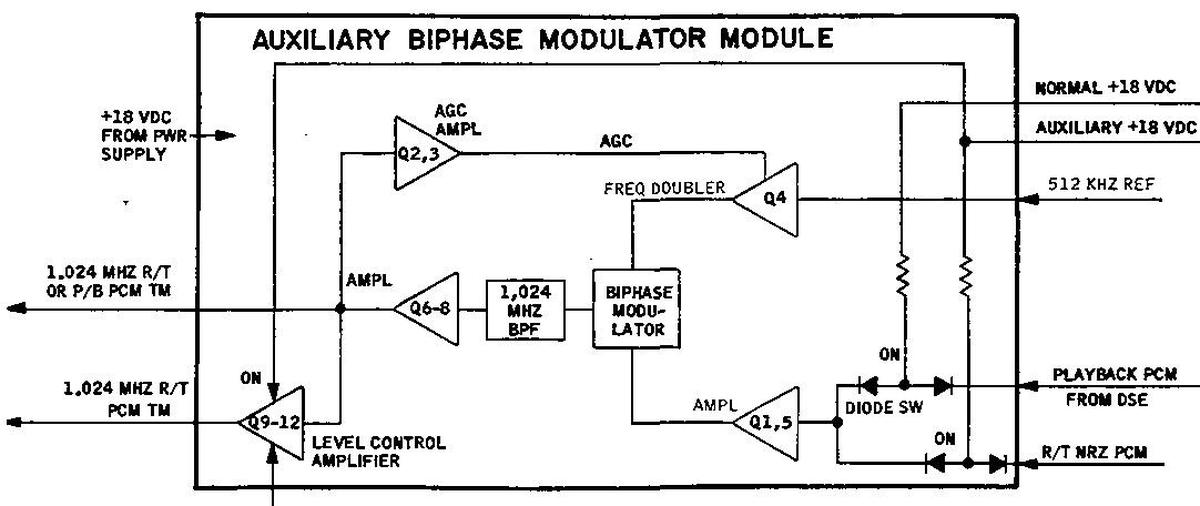

The auxiliary bi-phase modulator (below) is roughly the same as the normal modulator, but with a bit more circuitry to switch between modes, transmitting either recorded PCM data from tape or real-time PCM data, using the PM or FM transmitters. Curiously, the different modes are selected by switching the power supply between NORM and AUX. In NORM mode, the auxiliary module transmits recorded data over FM. In AUX mode, the auxiliary module transmits real-time data over both PM and FM, providing a backup in case the normal module fails.

The output signals from the bi-phase modulators are processed either by the FM mixer / LM PCM limiter module or the PM mixer / key / TV module; these are discussed later.

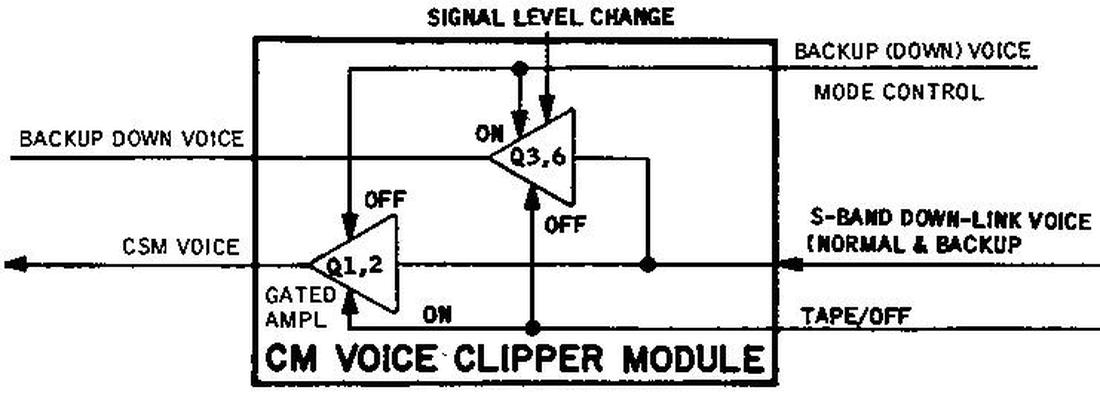

Voice clipper module

Voice communication from astronauts to the ground ("downlink voice") went through multiple stages of processing to improve quality. The design standard for the Apollo audio system was 90% word intelligibility for the main links and 70% for the backup links.9 This standard seems surprisingly poor, with one out of 10 words unintelligible, but achieving this standard was challenging due to the extreme distance to the Moon. Moreover, the spacecraft had a lot of ambient noise that interfered with communication. To maximize voice intelligibility over the available radio link, the voice signal was pre-emphasized and clipped. The voice clipper module (below) implemented the pre-emphasis and clipping of the voice signal.

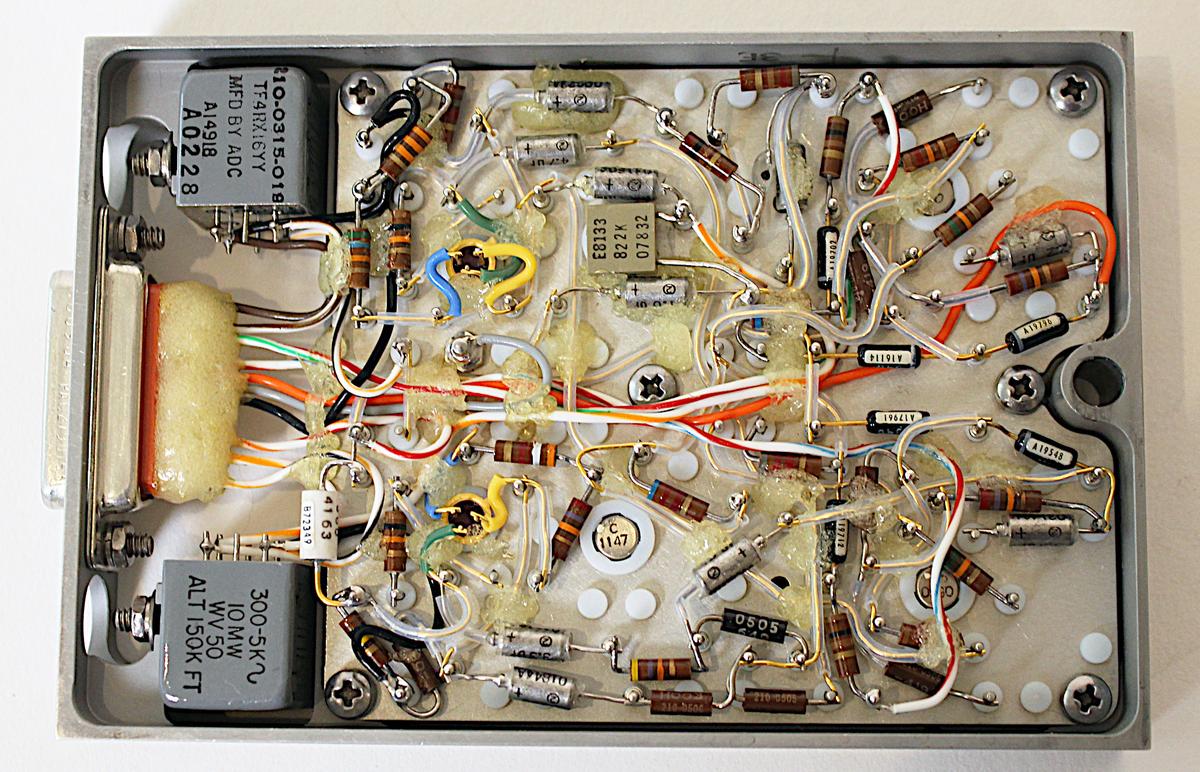

The photo below shows the voice clipper module. It has two gray audio transformers at the left. The remainder of the module is filled with circuitry.

The voice signal next goes to the voice relay module, discussed below. (The backup voice signal, however, went directly to the S-band transceiver for transmission to ground.)10

Voice relay module

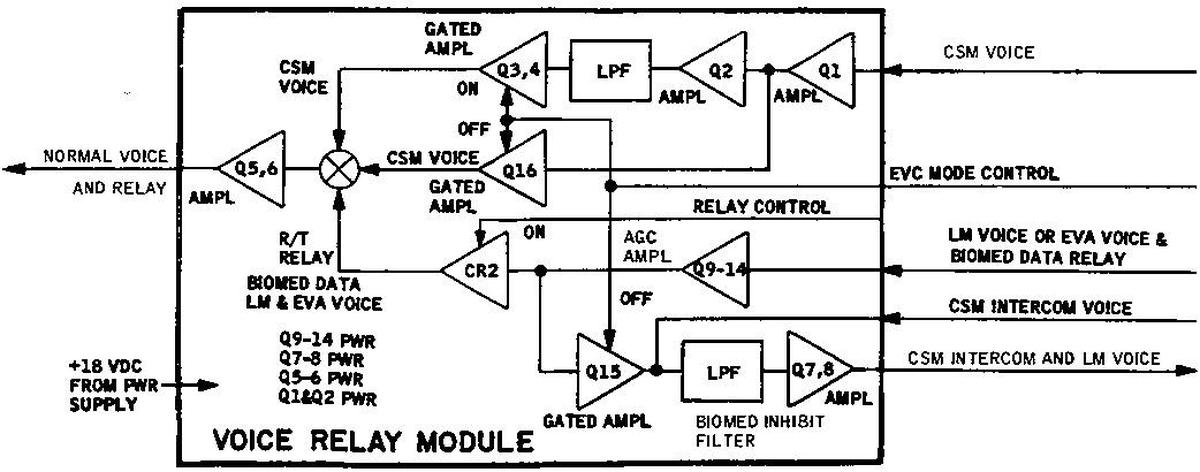

The voice relay module permitted voice communication from the Lunar Module to be relayed through the Command Module instead of being transmitted directly to Earth from the Lunar Module. If the S-band mode switch was set to "RELAY", the voice and biomedical data from the Lunar Module would be mixed in with the Command Module's voice signal and sent to Earth. This module also optionally applied a low-pass filter to the Command Module's voice signal, under the control of the VHF duplex switch. (I think this is so voice and biomed data can be sent over the same channel without frequency conflict.)

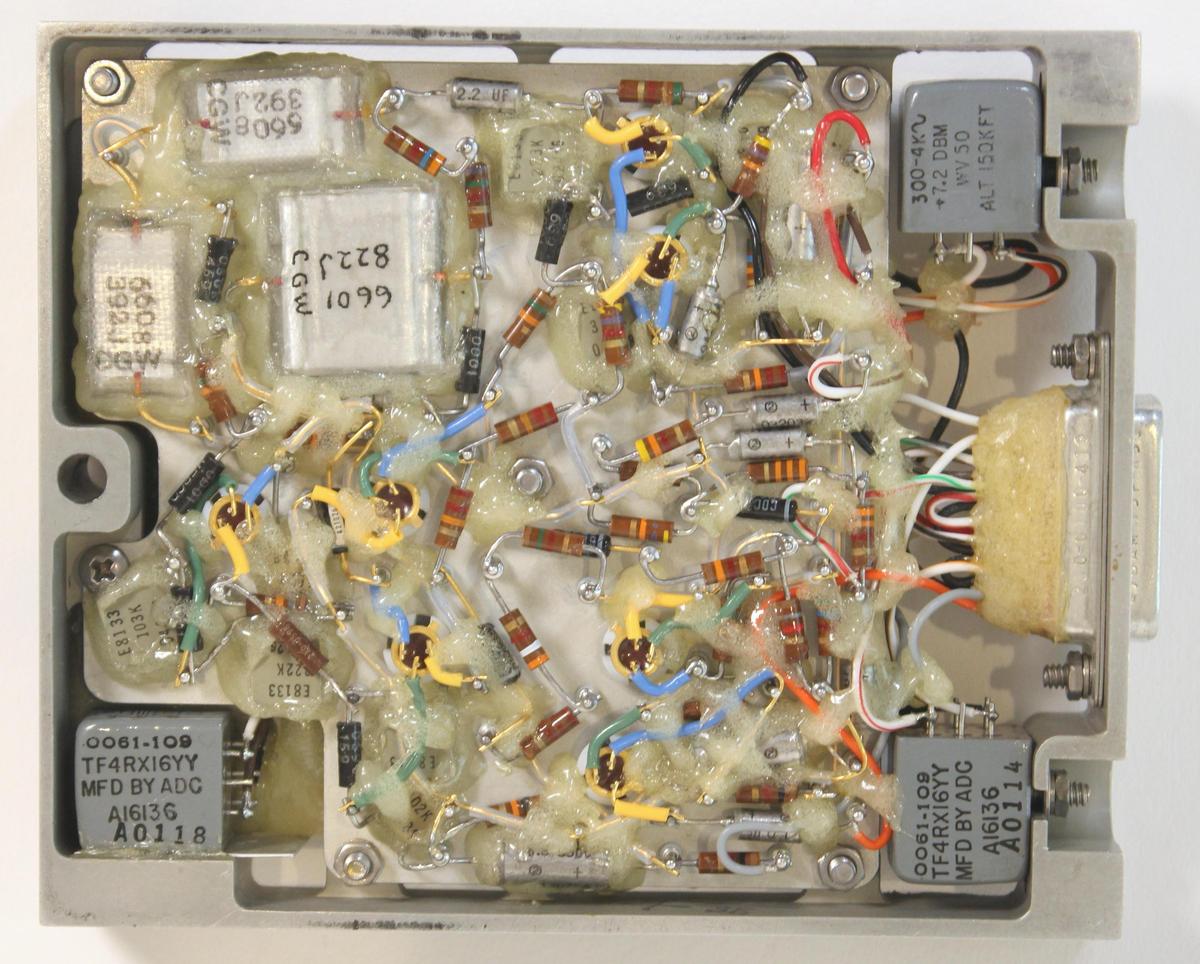

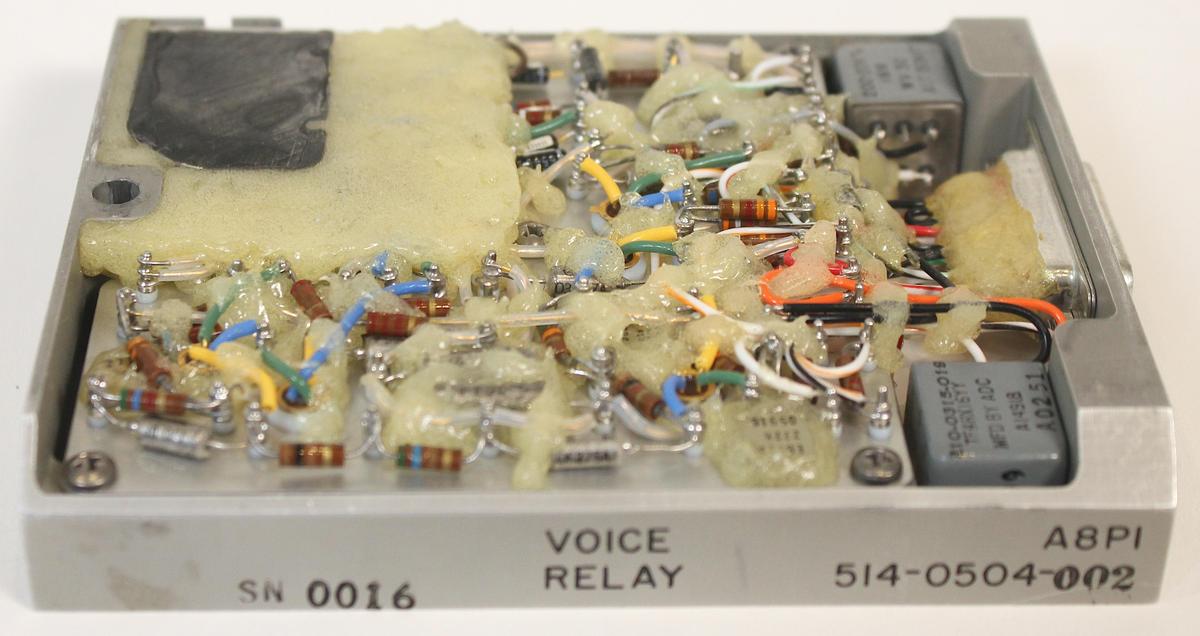

The photo below shows the voice relay module circuitry. There are three audio transformers, along with circuitry liberally encased in goo.

Flipping the module over, the upper right corner is completely covered in plastic. The reason for this is unclear. That corner holds one of the transformers, but I don't see a reason why this one in particular would be covered.

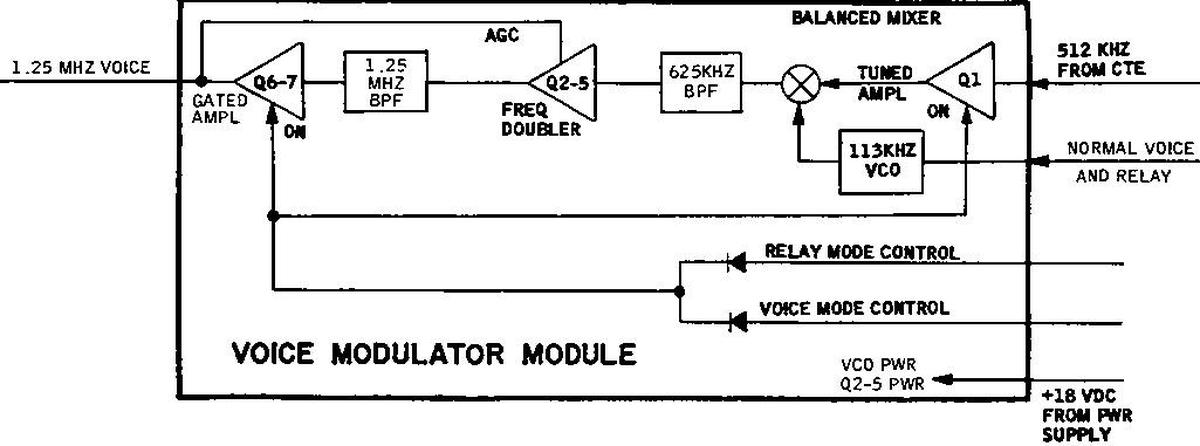

Voice modulator module

Next, the voice signal went to the voice modulator module, which used a complicated circuit to apply frequency modulation. First, the voice signal controls a 113-kilohertz voltage-controlled oscillator (VCO), yielding an FM signal at 113 kilohertz. Next, this signal is mixed with a 512-kilohertz signal from the central timing equipment (CTE), yielding signals at the sum and difference frequencies (399 kHz and 625 kHz). The bandpass filter passes the 625-kilohertz FM signal. The signal frequency is doubled and filtered to produce the final 1.25 MHz FM signal.

Three large modules are visible inside: the voltage-controlled oscillator and the two bandpass filters.

The other side of the module has the circuitry, wired to the larger modules. The frequency-doubler may be implemented by a varactor diode, but I haven't located it. From the voice modulator, the voice signal passed to the PM mixer / key / TV module.

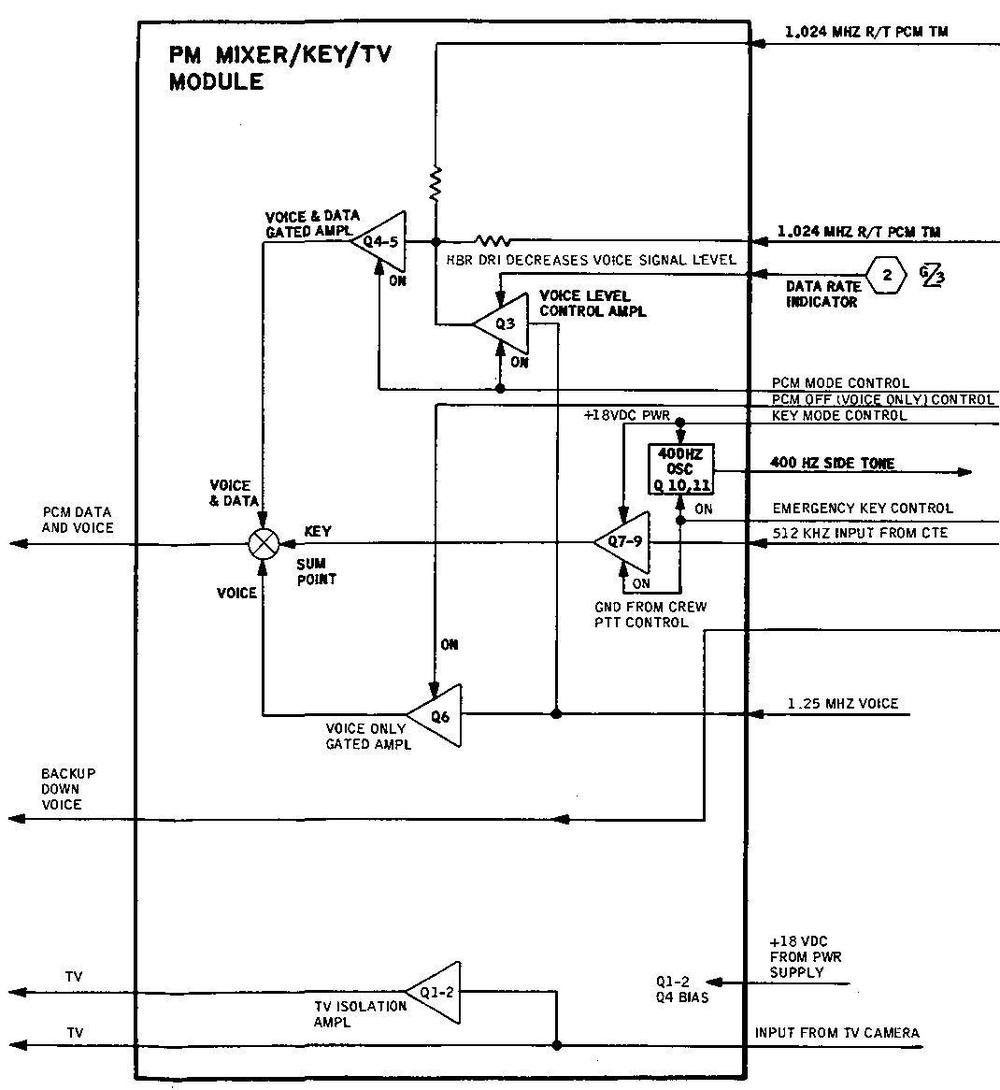

PM mixer/key/TV module

As the name suggests, the PM mixer/key/TV module had multiple functions. In the top part of the diagram below, the mixer combines three data sources: voice with data, emergency keying, and voice. The voice and data combination consists of PCM data at 1.024 megahertz with voice data at 1.25 megahertz; the PCM data is provided by one of the bi-phase modulator modules, while the voice data is provided by the voice modulator module. The next mixer input is the emergency key signal. The purpose of emergency key is that if voice communication failed, an astronaut could send Morse code by using the XMIT key on their communication cable. This key signal might be able to get through to Earth even if voice communication fails or is unintelligible. This module produces the emergency key signal at 512 kHz along with a 400 Hz feedback tone for the astronauts. The final mixer source is voice. The sum of these signals is sent to the S-band PM transponder for phase modulation and transmission. This module also includes a TV isolation amplifier to supply a TV signal to ground support equipment (GSE) before launch.

The photo below shows this module. On the front right is a component that looks a bit like a power transistor. However, it is an adjustable component (note the screw in the middle), probably a variable resistor.

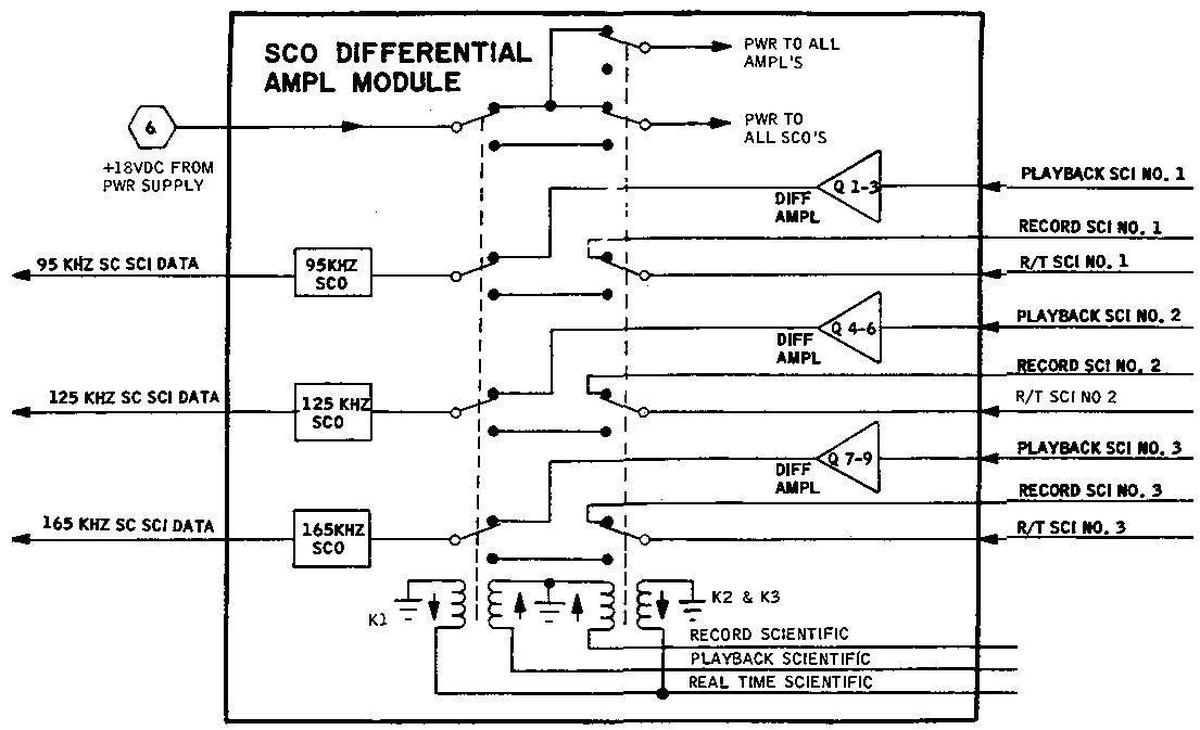

SCO (subcarrier oscillator) and differential amplifier

This module is used for transmitting three channels of analog scientific data. (This is in contrast to most of the data, which was transmitted digitally, using pulse-code modulation (PCM).) Each of the three scientific signals modulates a subcarrier oscillator on a different frequency: 95 kHz, 125 kHz, and 165 kHz. These signals are sent to the FM mixer / LM PCM limiter module, which will be discussed in the next section.

This module also contains relays so the real-time scientific data could be directed to tape for storage. The recorded data could be played back for transmission, amplified by the differential amplifiers. The mode was controlled by the S-band Aux TV/SCI switch. If set to SCI, real-time scientific data was transmitted. If the transmitter was used for TV, the scientific data was recorded to tape for later playback. The tape recorder switch was set to PCM/ANLG to play back the analog data.

Inside, the three large tan oscillator modules are visible. The three relays are the smaller grayish boxes. This module has the D-Sub connector attached with wires and rotated 90°, unlike the other modules that have the connector mounted to the end of the module.

On the other side of the module, the circuitry is visible. Note the 6-pin transistors (gold and green circles). These probably contain two carefully-matched transistors for the differential amplifiers. The performance of a differential amplifier strongly depends on its two input transistors; by putting the transistors in the same package, the effects of temperature are minimized.

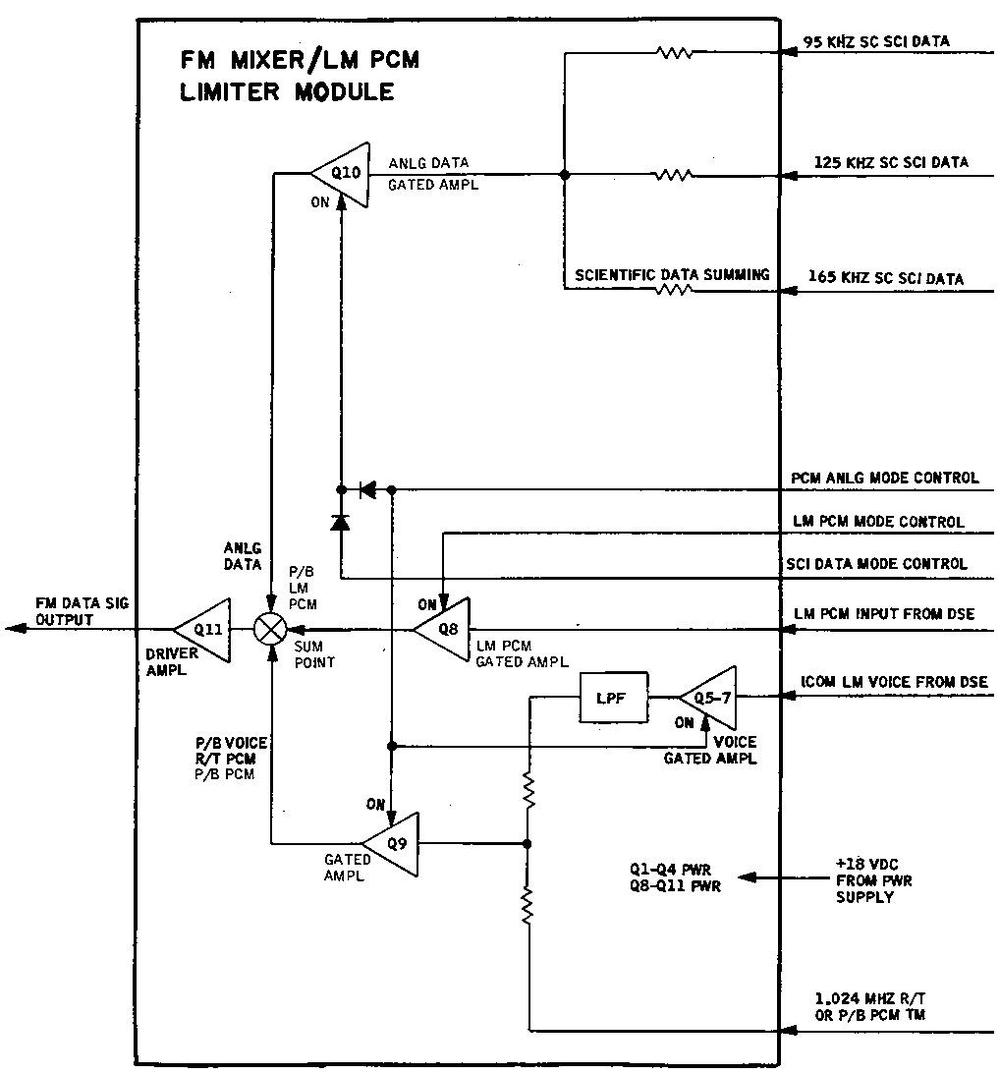

FM mixer / LM PCM limiter module

The final module is the FM mixer / LM PCM limiter. Like the PM mixer module, this module combines multiple signals for transmission. But this module prepares signals for FM transmission rather than PM transmission. Specifically, the module combines the three analog scientific data inputs, digital PCM data from the Lunar Module, intercom voice from the Lunar module, and PCM data modulated at 1.024 MHz. Various switches on the console control the different modes.

The photo below shows the module's circuitry. It has four gray transformers along with the typical transistors, diodes, resistors, and capacitors.

The unusual feature of this module is the encapsulated module in the upper left. This module appears to contain three transistors and five capacitors. It's unclear why these components are encased in plastic. The block diagram for this module doesn't show any special circuitry that would motivate encapsulation. I hope to reverse-engineer this module to figure this out.

Conclusion

Well, I had planned to write a quick description of what we saw inside the premodulation processor but it turned out to be much more complicated than I expected. Congratulations on making it to the end of this blog post.

The premodulation processor illustrates how analog electronics were very bulky before integrated circuits became popular. In the modules, amplifiers and other functional blocks were built from discrete components. The result was a 14.5-pound box to perform a few signal processing tasks. A decade later, many of the circuits could have been replaced with compact ICs.

The premodulation processor also shows how complex everything was in Apollo. You might think that transmitting voice, data, and TV wouldn't be too tricky, just three signals. But everything needed to be redundant. Then there were special cases, such as recording data when you're on the far side of the Moon. Or communicating between astronauts in the Command Module, in the Lunar Module, and walking on the Moon. All these cases required circuitry to switch signals and optimize the radio link for each mode. And the premodulation processor is just one of many boxes in the Apollo communications system! Apollo is like a fractal, where you find successive layers of complexity as you look closer at any system.

We haven't been able to find detailed schematics of the premodulation processor modules, so I plan to reverse-engineer some of the circuitry. I announce my latest blog posts on Twitter, so follow me @kenshirriff for updates. I also have an RSS feed. Thanks to Marcel for providing the premodulation processor and letting Mike, CuriousMarc and me disassemble it.

Notes and references

-

The Apollo Operations Handbook: Telecommunications System gives this description: "The premodulation processor (PMP) equipment provides the interface connection between the airborne data-gathering equipment and the RF electronics. The PMP accomplishes signal modulation and demodulation, signal mixing, and the proper switching of signals so that the correct intelligence corresponding to a given mode of operation is transmitted." ↩

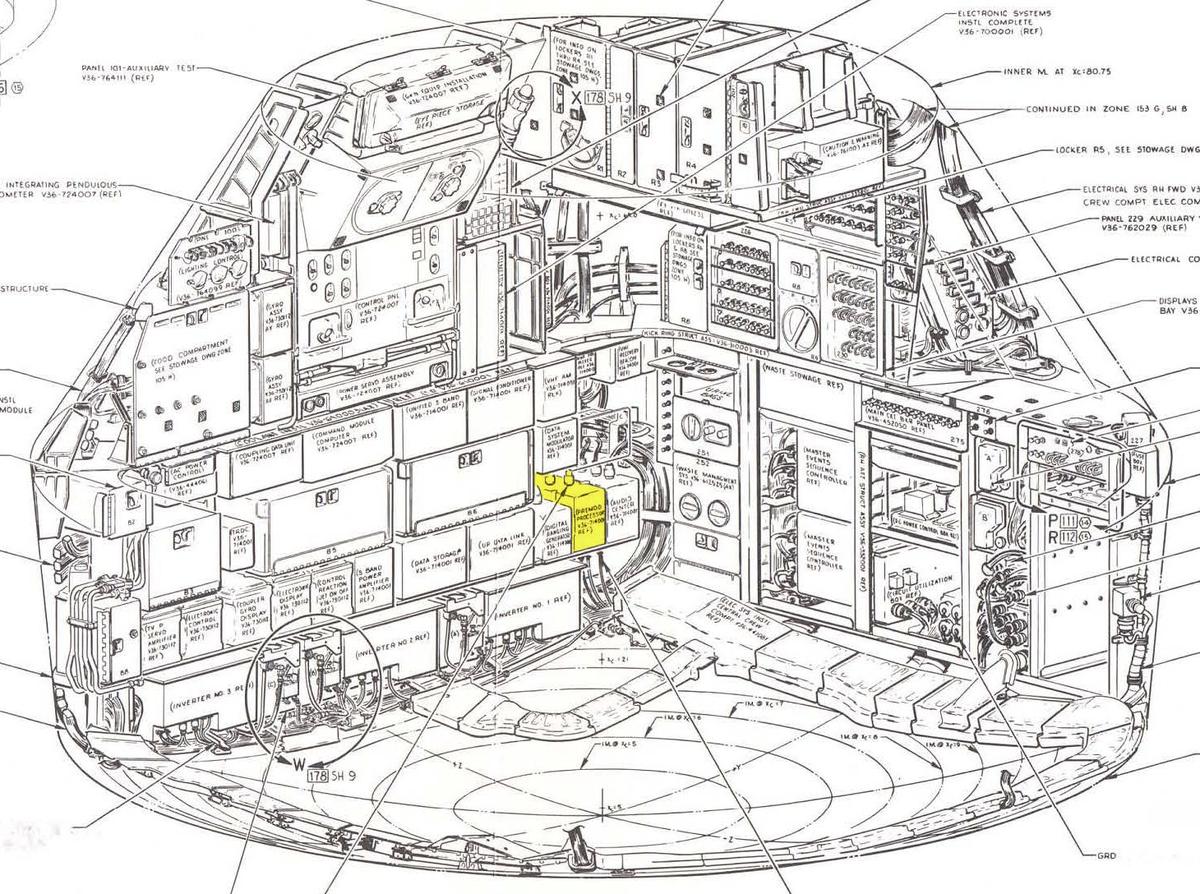

-

The premodulation processor was one of many boxes of electronic circuitry packed into the spacecraft and linked by thick cables. The diagram below highlights where it was mounted in the lower equipment bay of the Apollo Command Module.

The premodulation processor was one of many electronic boxes in the Command Module's lower equipment bay. Diagram from Command/Service Module Systems Handbook p212. -

The block diagram below shows the functions of the premodulation processor, along with the switches that control it.

A block diagram of the premodulation processor. From Apollo Operations Handbook: Telecommunications System.The block diagram below provides a more detailed view of the premodulation processor. I split out the sub-module diagrams for the discussion, but the full diagram shows the interconnections between the modules.

Block diagram of the PMP. (Click for a larger version.) From Command/Service Module Systems Handbook p63. -

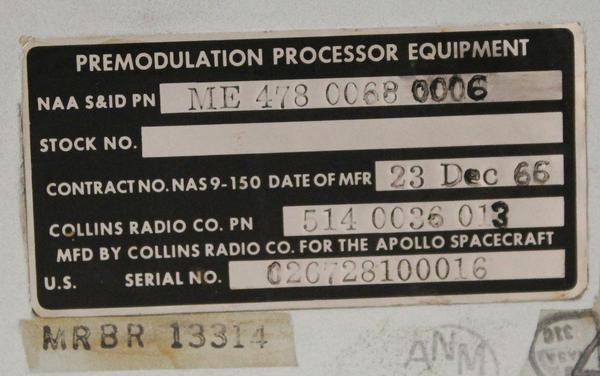

As shown by the nameplate, the premodulation processor was built by Collins Radio in 1966, two days before Christmas. Collins Radio built much of the communications equipment for the space program from Mercury through Apollo including the Deep Space Network antenna system, microwave links, and ground support equipment (details).4

The nameplate for the premodulation processor shows that it was built by Collins Radio. -

The backplane is a sheet of metal with D-Sub connectors for each module. The round connectors are underneath, wired to the backplane by individual wires.

The premodulation processor's backplane links the modules to the external connectors.The four round military-style connectors are shown below. Two connectors have individual pins, while two connectors each have tiny coaxial connections.

The premodulation processor had four connectors for its numerous audio, RF, and control signals. -

We've examined several different Apollo electronics boxes and surprisingly they use completely different manufacturing techniques, even for boxes built by the same manufacturer. Techniques we've seen include printed-circuit boards, surface-mount components, cordwood modules, "dead-bug" components on a ground plane, point-to-point components, and encapsulated hybrid modules. I expected that there would be a standard manufacturing technique (like PCBs are standard now), but everything is different. ↩

-

The story of "Set SCE to Aux" is a well-known Apollo incident where disaster was averted. In brief, Apollo 12 was struck twice by lightning just seconds after launch. Inside the spacecraft, so many warning lights lit up that astronaut Conrad thought "the whole board looks like a Christmas tree". On the ground, consoles started displaying nonsense telemetry. Everyone was mystified until engineer John Aaron recalled seeing similar garbled telemetry during a test. He knew the solution and gave the puzzling command "Try SCE to Auxiliary". This switch was so obscure that astronaut Conrad responded, "What the hell is that?" Fortunately, astronaut Bean flipped the switch, bringing the SCE unit back to operation and restoring telemetry. There were other consequences of the lightning strike, but after the fuel cells were brought back online and the inertial guidance system was realigned, the spacecraft continued uneventfully to the Moon.

The underlying problem was that the lightning strike caused the spacecraft's fuel cells to go offline. The DC voltage bus was supposed to be at 28 volts, but the loss of the fuel cells caused the voltage to sag to about 18 volts. Within milliseconds, the voltage climbed to 24 volts under battery power, still low. The low voltage caused the primary power supply of the SCE (signal conditioning equipment) to shut down. Since the SCE's role was preparing dozens of analog sensor voltages for telemetry, this caused the telemetry values to Mission Control to be garbled. Flipping the SCE switch to Aux caused the SCE to use its auxiliary power supply, restoring the SCE to operation.

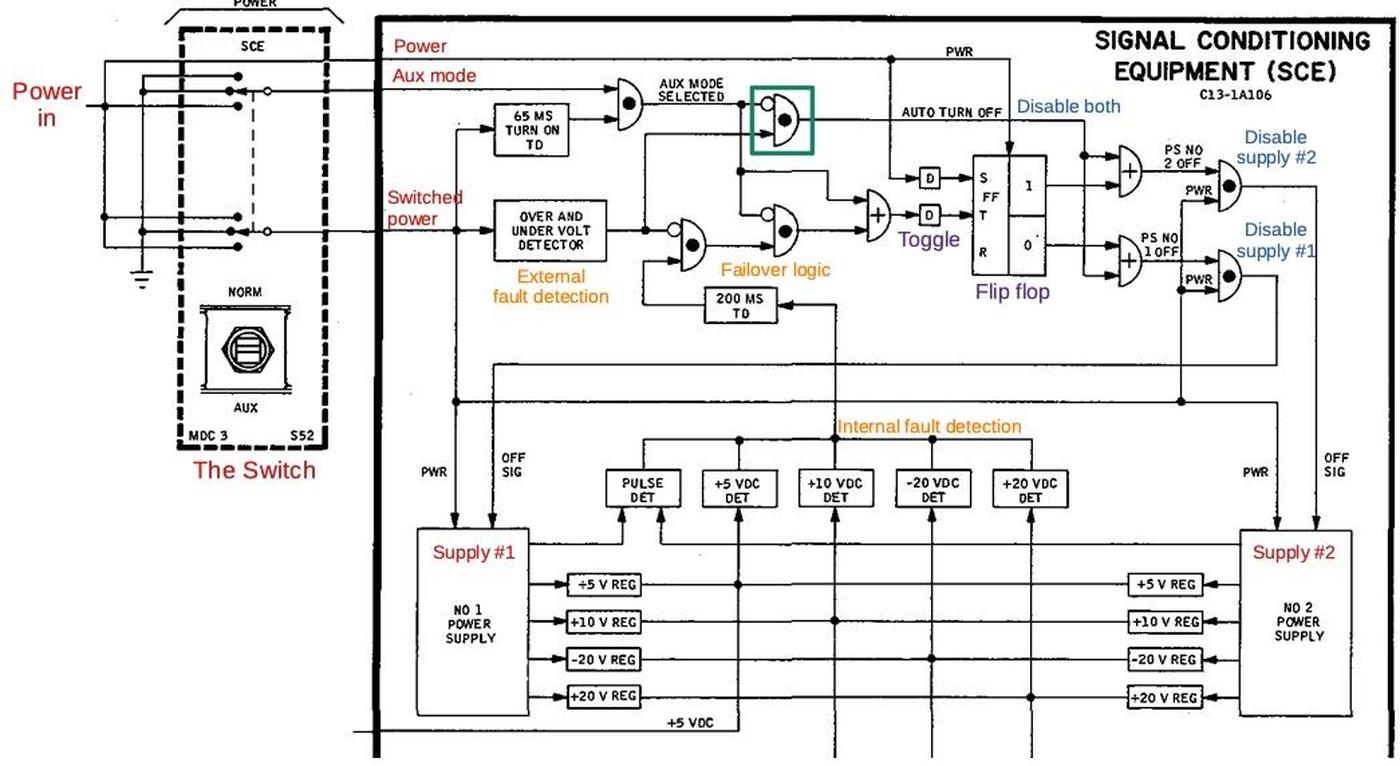

The published descriptions of this incident are vague on exactly why the auxiliary power supply worked when the primary didn't, so I looked at the SCE diagram (below) to fill in a few details. Power enters at the left and passes through the SCE's famous power switch, which has three positions: NORM, OFF, and AUX. Inside the SCE, there are two power supplies (red) for redundancy, along with some control circuitry at the top. One of the two power supplies is active at a time, unless both power supplies are deactivated for an overvoltage or undervoltage condition.

Diagram of the SCE power supply and the switch. From Command/Service Module Systems Handbook p118.The SCE has a flip flop (purple) that selects a power supply by disabling (blue) the unused one. When you switch SCE to AUX, one action is that it toggles the flip flop, switching from supply #1 to #2, or #2 to #1. But I don't think that was important for Apollo 12. AUX mode also blocks the undervoltage signal via an AND gate (green). That is, if the input voltage was still too low, both power supplies would be shut down in NORM mode but either one could function in AUX mode. This, I think, is why "SCE to AUX" powered up the SCE.

Another interesting feature is the automatic failover (orange). In NORM mode, the SCE will automatically switch power supplies if an internal voltage is bad for 200 ms. However, the failover logic is blocked by the undervoltage detector, so it would not have taken place in Apollo 12. But otherwise, if one of the power supplies failed, the SCE would transparently switch to the other one.

Curiously, the official NASA report Analysis of Apollo 12 Lightning Incident barely has two sentences on the SCE in its 94 pages. Although the SCE gets all the public attention in this incident, it seems like NASA didn't really care about it since the telemetry wasn't critical to the mission. NASA was much more interested in other effects of the lightning strike: the fuel cell shutdown, the effects on the computer and guidance systems, 9 failed sensors, and potential effects on the pyrotechnics. For more on the Apollo 12 incident, see the transcript, the detailed Scott Manley video, and an Apollo Flight Journal post.

Note that the SCE's power supply logic is different from other units. Most units (such as the transponder, TWT amplifier, and premodulation processor) have primary and secondary power supplies, with a switch to explicitly select one or the other. However, in the SCE, the Aux switch toggles between power supplies, rather than selecting a specific auxiliary power supply. ↩

-

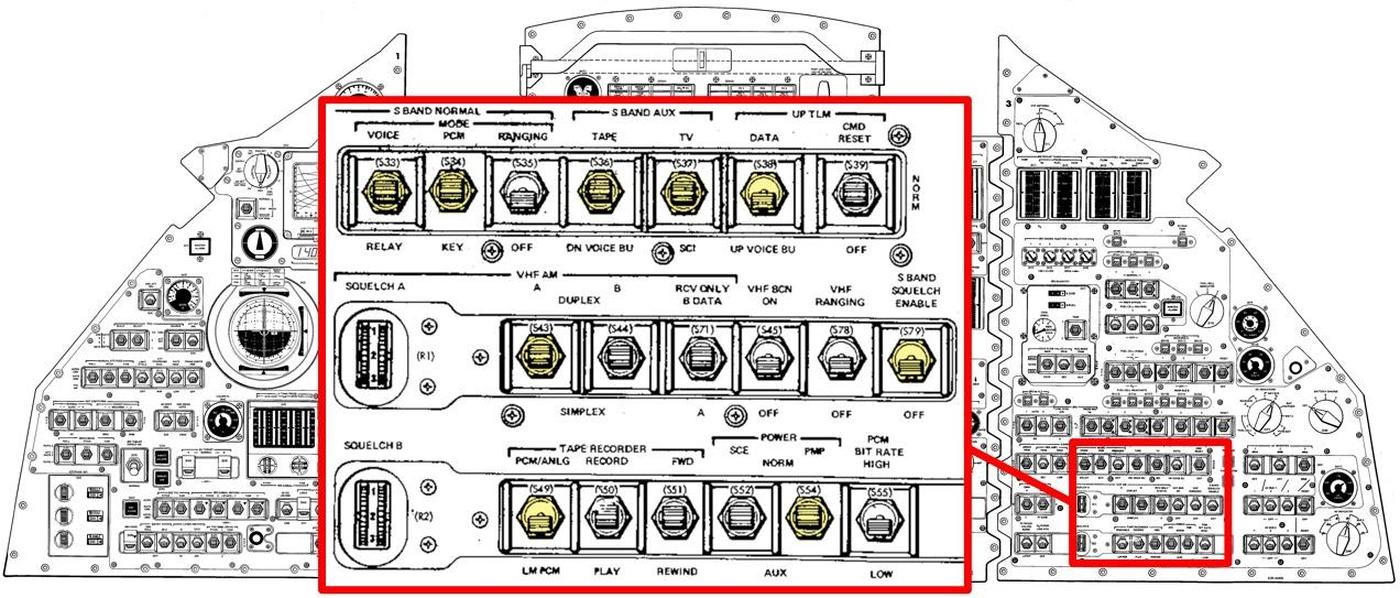

Astronauts used multiple switches on the control console to control the premodulation processor. These switches were grouped in the lower-right corner of the console with other communications switches. The diagram below shows the relevant switches, highlighted in yellow.

The Command Module console contains switches to control the premodulation processor. These switches are highlighted in yellow. Diagram based on from Command/Service Module Systems Handbook p208. -

For detailed information on the voice communication system, see Apollo Experience Report - Voice Communications Techniques and Performances. It discusses the performance requirements for the Apollo communications system and how the system was designed to achieve the intelligibility requirements. ↩

-

The idea of backup voice was to provide a voice channel for emergencies that used less power, at the cost of garbling up to 30% of the words. After the explosion, Apollo 13 used the backup voice system so they could turn off the Lunar Module's power amplifier and conserve electrical power. (See Apollo 13 Mission Operations Report pages N-2 and N-7, as well as the transcript.) Backup voice was also used at times during Apollo 16 due to a failure of the Lunar Module's steerable S-band antenna; see Apollo 16 Mission Report page 7-3, which calls this mode "down voice backup". (I should point out that these backup voice incidents involved the Lunar Module, not the Command Module's premodulation processor.) ↩